Lapping/polishing machine for intensive production of parts: Ø 5 to 210 mm

• Version S : with integrated pneumatic pressure system.

- Anchoring points dosing systems

- Rigid and stable chassis

- Mounting plate for pneumatic pressure system

- Height adjustable arms

- Anchoring points for AUTOPLAN®

- False plate supported by a ball bearing.

Take control of your honing and polishing operations by creating new recipes, and evolve them using the programming interface for the machine and peripherals.

SMART LAPPING

Intuitive multi-step programming, with the option of storing up to 45 5-step programmes.

M.M.9700

PREMIUM SERIES

Equipped with a 700 mm Ø honing plate, this machine features a highly intuitive touchscreen interface, making it easy to get to grips with the equipment.

-

Plate Ø700 mm

-

Plate rotation speedFrom 30 to 90 rpm

-

Inner ring Ø274 mm

-

Weight (without plate)500 kg

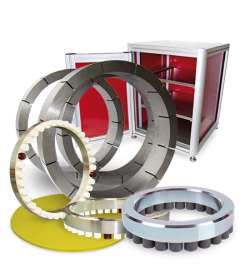

From a mechanical point of view, a large ball thrust bearing has been inserted under the machine’s sub-platen. This ensures the stability of the plate, even under heavy loads. This new design also reduces the stress on the gearbox, ensuring a long service life for the equipment. Machine safety has also been improved with anti-pinch devices coupled to the castors of the self-encoding ring support arms.

In order to meet the most demanding specifications in terms of surface flatness and process repeatability, LAM PLAN has developed the M.M.9000 series of machines, of which the M.M.9700 is the mid-range model.

Equipped with a 700 mm Ø honing plate, this machine features a highly intuitive touchscreen interface, making it easy to get to grips with the equipment.

The new design of the electrical part makes it easy to upgrade the machine’s functions to meet your changing needs, with, for example, the subsequent integration of the AUTOPLAN system or the different types of LAM PLAN dispensing feeders.

This machine is therefore designed for all production workshops where large quantities of parts need to be processed.

M.M.9700 version E

Ø 700 mm lapping machine without pressure system.

M.M.9700 version S

The S version of the M.M.9700 incorporates a pneumatic pressure system controlled electronically from the general interface.

Comprising three double-acting cylinders and three aluminium discs mounted on ball joints, this system eliminates the need to handle weights, optimising loading and unloading times and reducing handling effort. This optimises loading and unloading times and reduces handling effort.

The applicable pressure can vary from 100 to 1000 N.

Design and advanced technology

Technical characteristics and equipment

Options for M.M.9700 E and S

-

LED light option (for S versions)10 9000S 10

-

Multi-abrasive option10 9000S 20

-

Level sensors for diamond liquid and lubricating fluid08 90001 00

-

Torque spanner set60 01485 90

Downloads

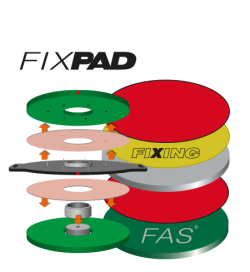

Plug & play

Whether electrical or pneumatic, the connectivity of the machines has been designed to accommodate production support accessories in a simple way. When you plug in a piece of equipment, it is immediately recognised by the machine control system.

Control and programming

Take control of your honing and polishing operations by creating new recipes, and evolve them using the programming interface for the machine and peripherals.

Integrated modem

All M.M.9000 PREMIUM series machines come with an integrated modem for remote maintenance of the PLC.

They are compatible with dedicated LAM PLAN dosing units and can be fitted with an optional abrasive and lubricant level sensor.

Production data can be collected via the USB interface. Recipes can be imported and exported in CSV format. Recipes can be modified via Excel before being imported back into the machine.

Mechanical design

Integrating a LAM PLAN lapping solution goes beyond what is offered by conventional equipment on the market. We design machines ready to withstand the highest stresses.

M.M.9700 data sheets

M.M.9700 version E | M.M.9700 version S |

|

|---|---|---|

|

Visuals

|

|

|

|

Plate Ø

|

700 mm

|

700 mm

|

|

Inner ring Ø

|

274 mm

|

274 mm

|

|

Capacity per ring

|

1 part Ø 210 mm or 160 parts Ø 10 mm

|

1 part Ø 210 mm or 160 parts Ø 10 mm

|

|

Number of rings

|

3

|

3

|

|

Electric power supply

|

400 V – 50 Hz – 3 phases + ground + neutral

|

400 V – 50 Hz – 3 phases + ground + neutral

|

|

Motor Power

|

2.2 kW

|

2.2 kW

|

|

Control

|

7-inch touch screen

|

7-inch touch screen

|

|

Plate rotation speed

|

From 30 to 90 rpm

|

From 30 to 90 rpm

|

|

Pressure application system

|

–

|

3 adjustable double-acting pneumatic cylinders

|

|

Applicable pressure

|

–

|

100 to 1000 N

|

|

Type of stem

|

–

|

Fixed

|

|

Dimensions (W x H x D)

|

1500 x 1300 x 1450 mm

|

1500 x 1300 x 1900 mm

|

|

Weight (without plate)

|

500 kg

|

600 kg

|

|

Système de distribution abrasif

|

En option

|

En option

|

|

Reference

|

10 9700E 00

|

10 9700S 00

|

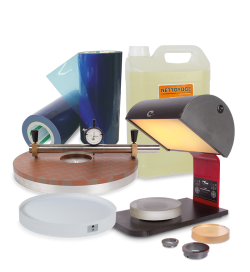

Available accessories

Stem E

Accessory support for LAM PLAN lapping machines (VERSION E).

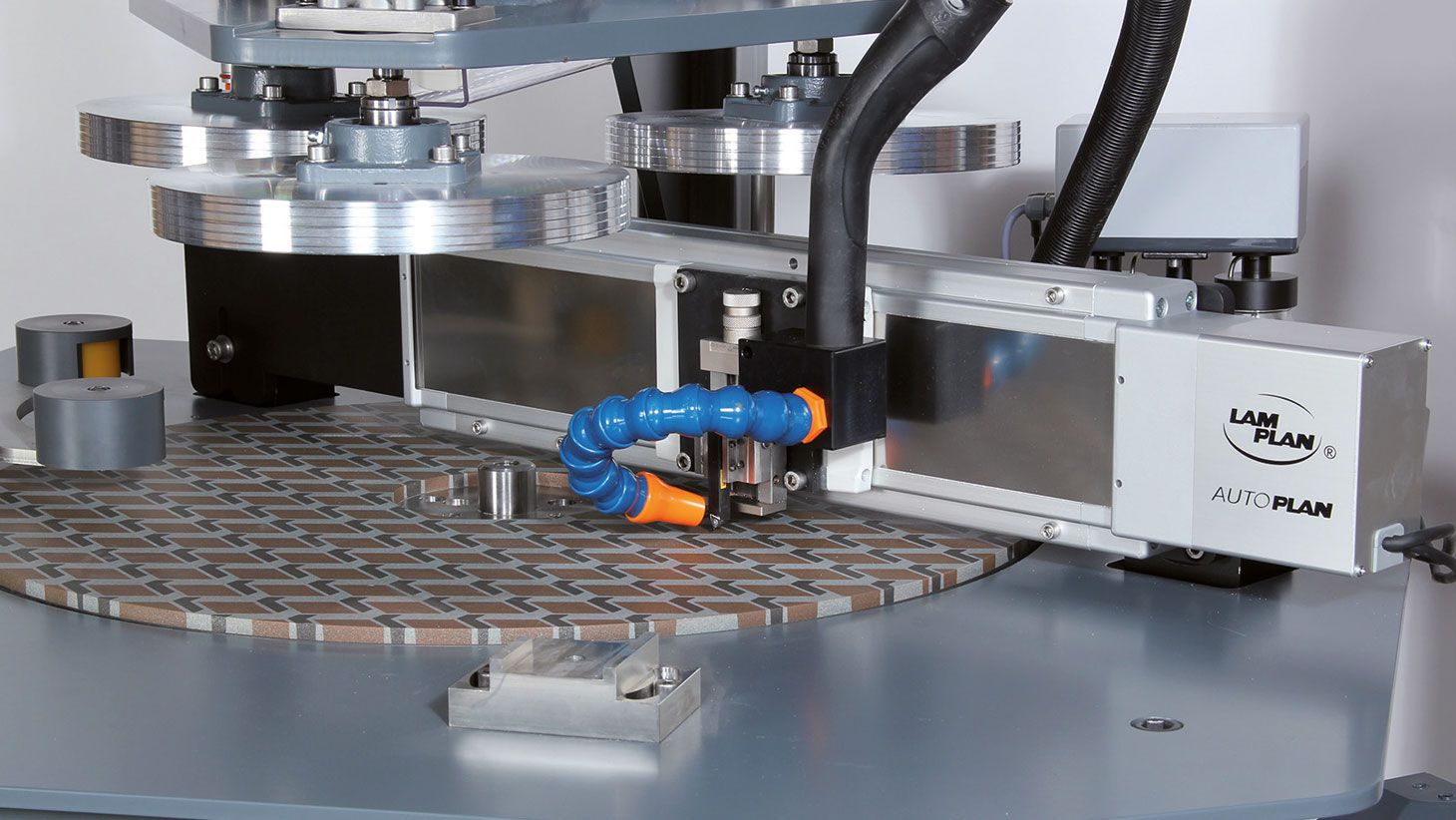

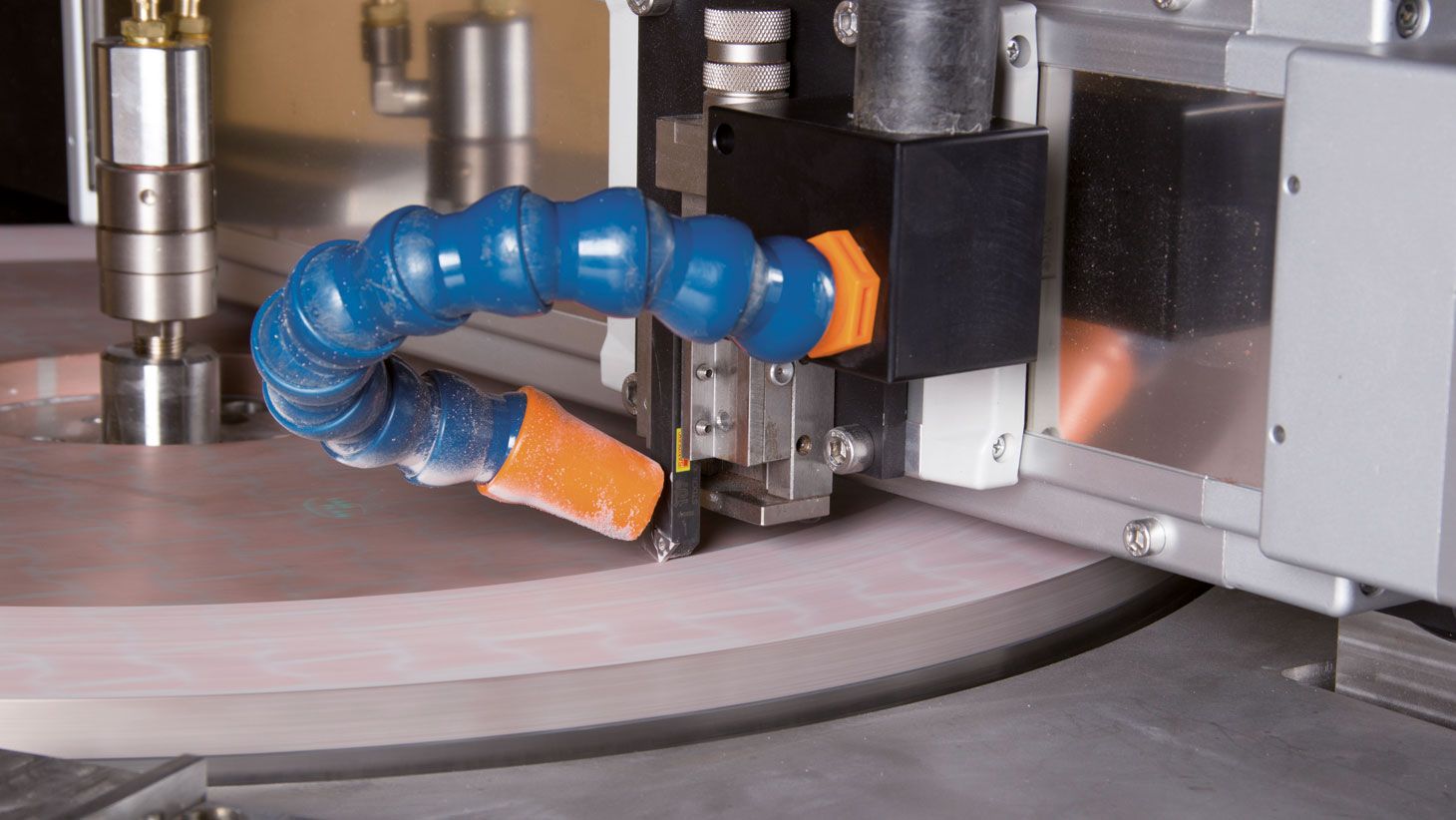

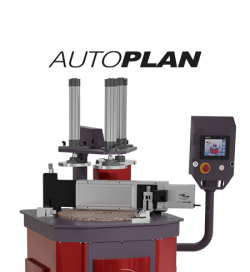

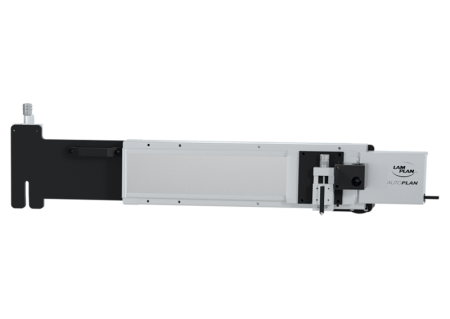

AUTOPLAN system with support trolley

The AUTOPLAN system enables efficient plate flatness and grooving in order to create structures which modifier it’s properties.

The principle lies in plate machining with a moving cutting tool.

The AUTOPLAN is positioned and mounted in a few minutes thanks to the dedicated fixation points integrated in our machines.

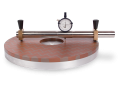

Micrometric gauge

For a fast and precise check of your lapping plates, with a direct reading of the measurements. Precision: 1 µm.

The transport and storage case includes :

- 1 marble, accuracy : 0,8 µm.

- 1 gauge made of stabilised aluminium or stainless steel for machines Ø 200 to 600 mm.

- 1 micron comparator.

- 1 user guide with charts and mapping formulas.

Material removal control MESUREO

MESUREO assembly with storage case

Material removal control, compatible with the M.M.9400, 9380 and 9480 machines, enabling flat surfaces to be obtained to less than one micron, combined with parallelism of less than 5 microns between the lapped face and a reference. The MESUREO consists of a perfectly flat ceramic-coated pressure disc that moves on a vertical axis. This tool is equipped with a wireless probe, enabling the removal of material to be displayed in real time on a PC placed close to the lapping machine. The target dimension can be set. Using a highly intuitive set of colours, the operator can quickly see on his computer monitor whether the parts are within the defined thickness tolerance.

Temperature control system P803

Flat lapping is based on the laws of mechanics and physics where a constant temperature is essential.

To control plate flatness, temperature must be regulated. The LAM PLAN P803 temperature regulation unit is reversable. It can also raise the plate temperature before use. This enables lapping to start in optimum geometric conditions in any work environment.

The P803 regulator is designed to maintain the temperature between 2 set values. It is an autonomous machine which has its own command interface.

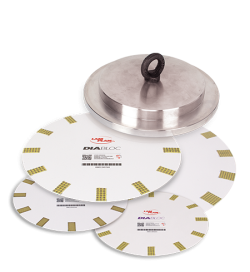

Dedicated dosing units

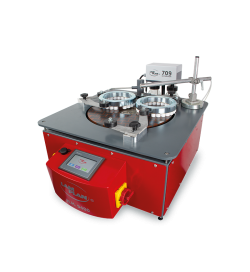

Peristaltic and venturi dosing units 709, 710 and 719

This series of dispensers is fitted to LAM PLAN lapping machines. They are controlled from the machine interface and are fully integrated into the programming cycles. The different models can be used to dispense all types of products.

Peristaltic and vortex mixing dispensers 8017, 8003 and 8007

These dispensing systems are suitable for any type of abrasive immersed in a liquid. They solve the problem of settling and guarantee regular and guarantee regular, repeatable results.