-

Plate Ø610 mm

-

Plate rotation speedfrom 30 to 90 rpm

-

Inner ring Ø248 mm

-

Weight400 kg

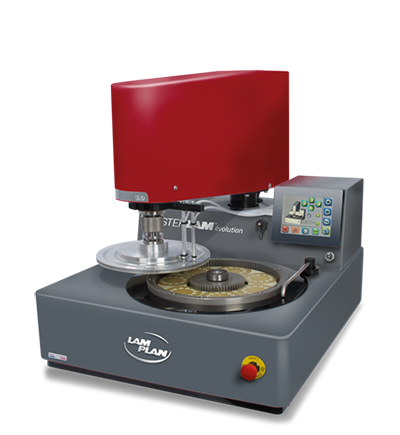

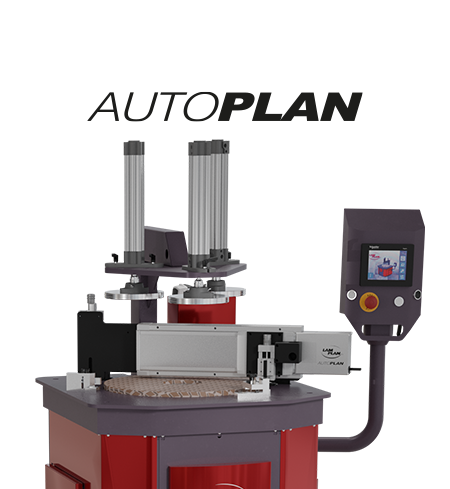

M.M.8600

M.M.8600 machines is a lapping/polishing device that allow you to add in your workshop a finishing tool for flat surfaces for a reasonable cost.

The compactness and the control ergonomic facilitate setting up and usage. Simple and proven, equipped with a medium size plate, it enable you to elaborate small production with controlled costs.

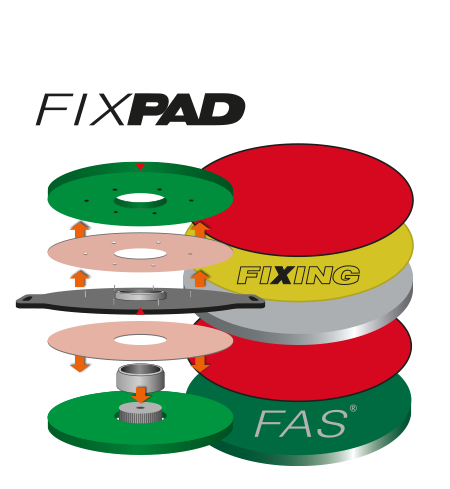

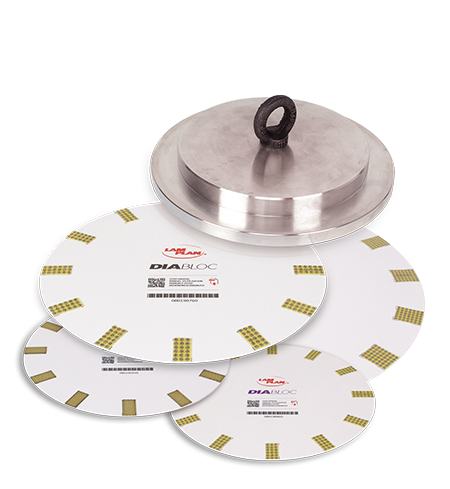

Equipped with cast iron, DIALAM®, NEW LAM M’M’® or FAS® plate, the machine will allow you to overcome all types of surface finishing defined by your specification (ex.: lapping, thickness abrasion, grinding, polishing…).

Technical characteristics

and equipment

These machines can be equipped with the patented NEW LAM® M’M’plates. The various proposed accessories (dosing unit, FAS® plates, polishing cloths….) allow adapting the basic machine to all specific applications (micromechanics, watchmaking industry, electronics, etc.)

Downloads

Technical data M.M.8600

Plate Ø | 610 mm |

Inner ring Ø | 248 mm |

Capacity per ring | 1 part Ø 210 mm or 320 parts Ø 5 mm |

Number of rings | 3 |

Electric power supply | 230 V single-phase |

Motor Power | 2.2 kW |

Control | 3.5 inches’ touch screen |

Plate rotation speed | From 30 to 90 rpm |

Dim. (W x H x D) | 1150 x 1150 x 1000 mm |

Weight (without plate) | 400 kg |

Abrasive distribution system | Included Type depending on the plate |

Reference | 10 86010 00 |

Available accessories

Dosing unit type 709

Peristaltic model dedicated to LAM PLAN machines.

- Capacity: 2 x 500 cc including 1 with agitator

- Electric power supply: 220V single phase + 24 V input for control

- Pump flow rate: 0,5 ml/sec.

- Distribution system: nozzles not included

Dosing unit type 710

Peristaltic model dedicated to LAM PLAN machines, recommended for oil-based products.

- Capacity: 2 x 500 cc including 1 with agitator

- Electric power supply: 220V single phase + 24 V input for control

- Pump flow rate: 0,5 ml/sec.

- Distribution system: nozzles not included

Dosing unit type 719

Peristaltic model dedicated to LAM PLAN machines, recommended for oil-based products.

- Capacity: 2 x 500 cc including 1 with agitator

- Electric power supply: 220V single phase + 24 V input for control

- Pump flow rate: N.C.

- Distribution system: nozzles not included

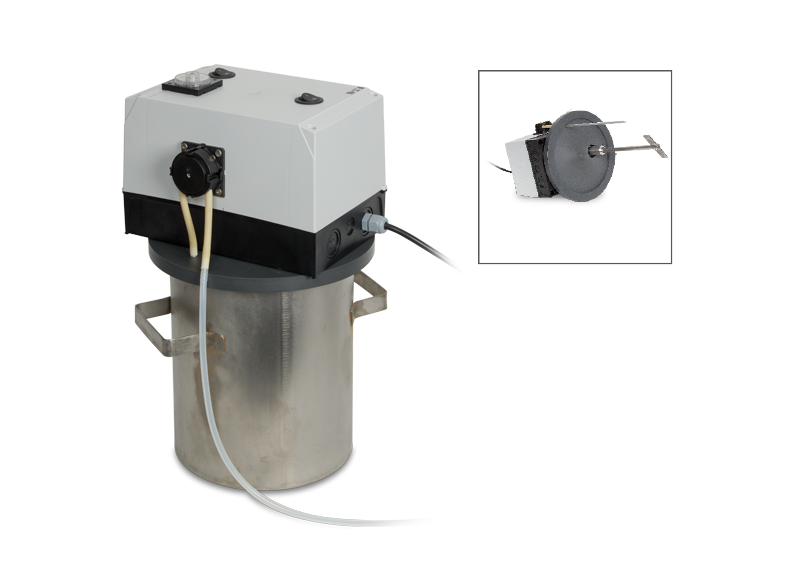

Dosing pump type 8017

Controlled by the machine interface or by integrated sequencer for the autonomous version.

- Pump type: 1 peristaltic pump + mixing system

- Bowl: useful volume 7 litres

- Electrical power supply: 220V single-phase

- Pump flow rate: 3,5 ml/sec.

- Distribution system: nozzle 813 on mobile stand supplied with the dosing unit

| Designation |

Qty. | Capacity | Ref. |

| Dosing pump type 8017 for LAM PLAN machine | 1 | 7 litres | 08 08017 00 |

| Indepedent dosing pump type 8017 | 1 | 7 litres | 08 18017 00 |

Dosing pump type 8003

Controlled by the machine interface or by integrated sequencer for the autonomous version.

- Pump type: 1 vortex pump + mixing system

- Bowl: useful volume of 50 litres, on casters, drain valve

- Electrical power supply: 220V single-phase

- Pump flow rate: 50 litres/minute

- Distribution system: 3 swivelling outputs. Solenoid valve 3 tracks controlled by the sequencer included with the pump.

| Designation |

Qty. | Capacity | Ref. |

| Dosing pump type 8003 for LAM PLAN machine | 1 | 50 litres | W000 08003 |

| Indepedent dosing pump type 8003 | 1 | 50 litres | W001 08003 |

Dosing pump type 8007

Controlled by the machine interface or by integrated sequencer for the autonomous version.

- Pump type: 1 vortex pump

- Bowl: useful volume 7 litres

- Electrical power supply: 220V single-phase

- Pump flow rate: 25 litres/minutes

- Distribution system: 3 swivelling outputs. Solenoid valve 3 tracks controlled by the sequencer included with the pump.

| Designation |

Qty. | Capacity | Ref. |

| Dosing pump type 8007 for LAM PLAN machine | 1 | 7 litres | W000 08007 |

| Indepedent dosing pump type 8007 | 1 | 7 litres | W001 08007 |

Autonomous dosing unit M.M.809B – Venturi

- Distribution system:

– Distribution of 2 different liquids by Venturi system

– 1 liquid compartment with an agitator - Control: By analog buttons and timers

- Compressed air feed system: 2 bars

- Electrical power supply: 220 V single-phase- 50 Hz

- Dosing machine communication: 1 x 220 V input for machine servoing

| Designation |

Qty. | Dim. | Ref. |

| Dosing unit M.M.809B | 1 | with 2 glass bottles 500 cc | 08 01809 10 |

Autonomous dosing unit M.M.909 – Peristaltic

- Distribution system: 3 standard peristaltic pumps with an outlet to drive an external pump

- Control: touch screen

- Electrical power supply: 220 V single-phase – 50 Hz

- Dosing machine communication: 1 x 24 V input for machine servoing

| Designation |

Qty. | Dim. | Ref. |

| Dosing unit M.M.909 ADAPTABLE VERSION With a manual start/stop button |

1 | with 3 glass bottles 500 cc | 08 03799 00 |

| Stirrer | 1 | for glass bottle 500 cc | 08 02816 00 |

Autonomous dosing unit M.M.909 HV – Peristaltic

- Distribution system: 2 standard peristaltic pumps, 1 large flow pump for high viscosity liquids and an outlet to drive an external pump

- Control: touch screen

- Electrical power supply: 220 V single-phase – 50 Hz

- Dosing machine communication: 1 x 24 V input for machine servoing

| Designation |

Qty. | Dim. | Ref. |

| Dosing unit M.M.909 HV | 1 | with 3 glass bottles 500 cc | 08 00799100 |

| Stirrer | 1 | for glass bottle 500 cc | 08 02816 00 |

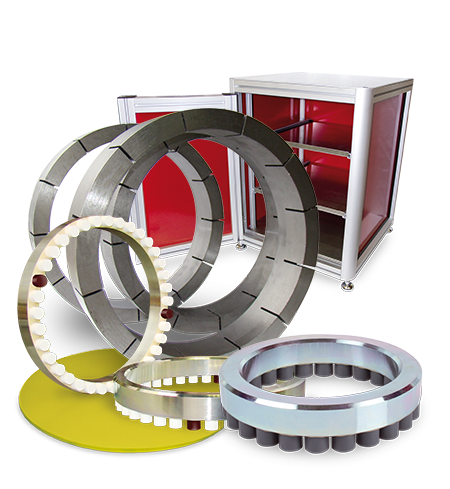

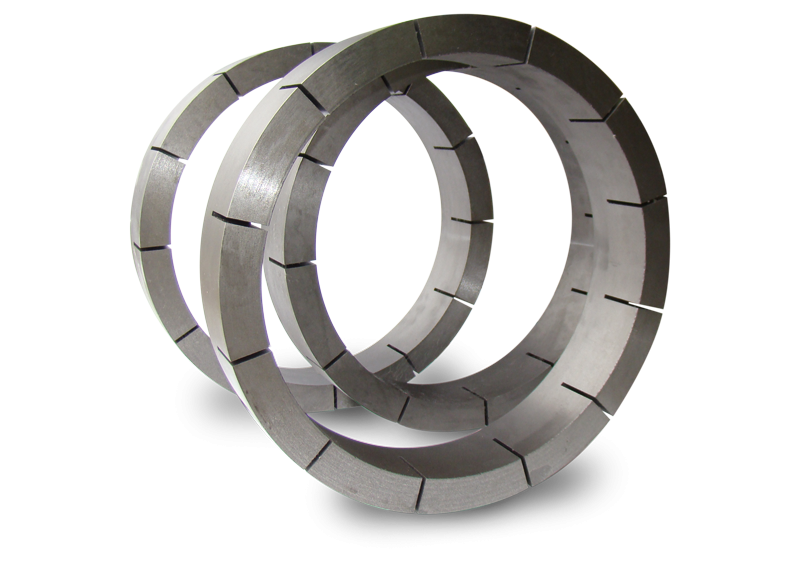

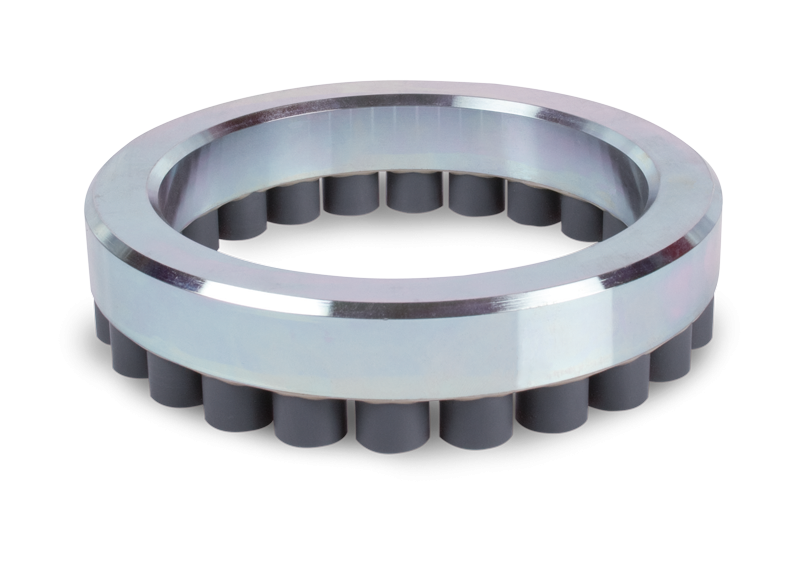

Cast iron conditioning rings 24″ (Ø 610 mm)

We carefully select special high quality cast iron for optimum, durable results. Suitable for all lapping machines, whatever the brand or size.

Available from stock or produced to order.

| Ø in mm | Qty. | Ref. | |

| Ext. | Int. | ||

| 286 | 248 | 1 | U286 A0610 |

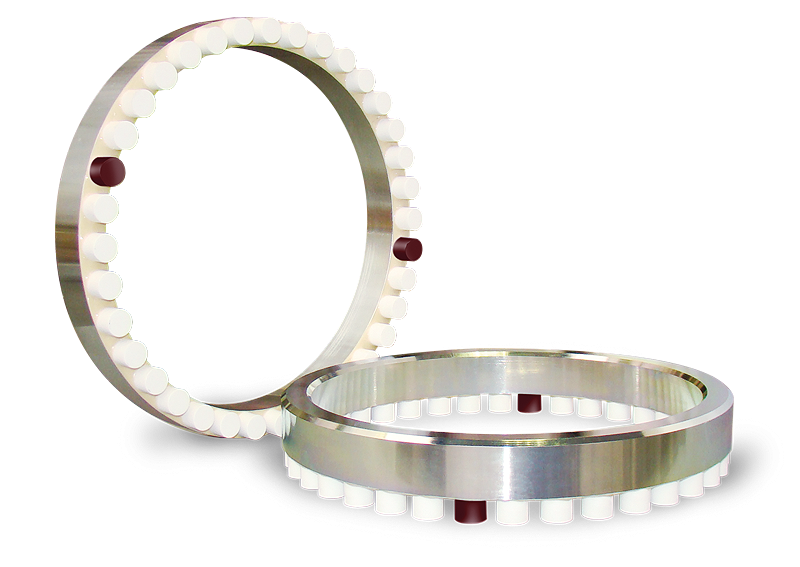

Ceramic conditioning rings with SPYLAP® 24″ (Ø 610 mm)

Prevent mechanical distortion problems. The ceramic rings enable you to preserve the flatness of the plate, to manage its heating, as well as limiting contamination thanks to the absence of graphite.

The SPYLAP® sensor enables the user to visually prevent a significant mechanical distortion of the lapping (or polishing) support and of the part to be lapped. The SPYLAP® permanently monitors the temperature of the support and changes from black to red at a precisely predefined temperature.

| Ø in mm | Qty. | Ref. | |

| Ext. | Int. | ||

| 290 | 248 | 1 | 08 81062 10 |

Plastic rings 24″ (Ø 610 mm)

| Ø in mm | Qty. | Ref. | |

| Ext. | Int. | ||

| 290 | 248 | 1 | 08 86512 00 |