Lapping plates

Cast iron AQUA LAM®, NEW LAM® M’M’, EVOLAM, 2000 Series & cooling system.

AQUA LAM® cast iron plates

As a manufacturer and designer of cast iron plates and rings, we select specific high quality cast iron for optimum and long lasting results. AQUA LAM® plates and rings are suitable for all lapping machines of any brand or size. Available from stock or made to order within the shortest deadlines, AQUA LAM® cast iron plates and rings offer exceptional value for money.

Lapping cast iron plates with radial grooving by default, available on request in full or with all types of grooves, Concentric, Helical and Linear.

AQUA LAM® cast iron plates

Radial grooved cast iron plate with LAM PLAN adaptation system, other machine adaptations on request.

| Dimensions Ø |

Thickness (according to lapping machine types) |

Ref. |

| 14” 355 mm | 25 – 40 mm | V0 14RA STD |

| 15” 381 mm | 25 – 40 mm | V0 15RA STD |

| 19” 480 mm | 25 – 40 mm | V0 19RA STD |

| 24” 610 mm | 35 – 40 mm | V0 24RA STD |

| 28” 700 mm | 55 mm | V0 28RA STD |

| 36” 914 mm | 57 – 58 mm | V0 36RA STD |

| 39” 1000 mm | 57 – 60 mm | V0 40RA STD |

| 1200 mm | 70 mm | V0 47RA STD |

| 48” 1219 mm | 70 mm | V0 48RA STD |

| 59” 1500 mm | 80 – 100 mm | V0 59RA STD |

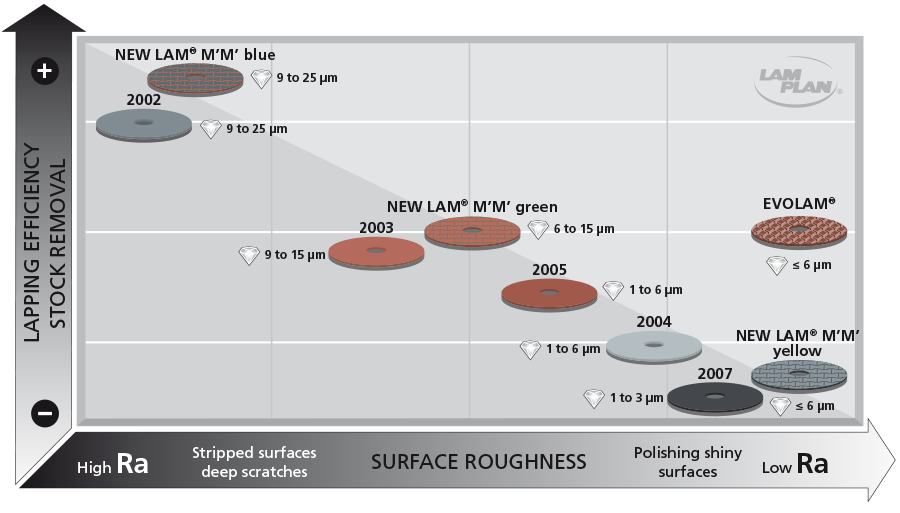

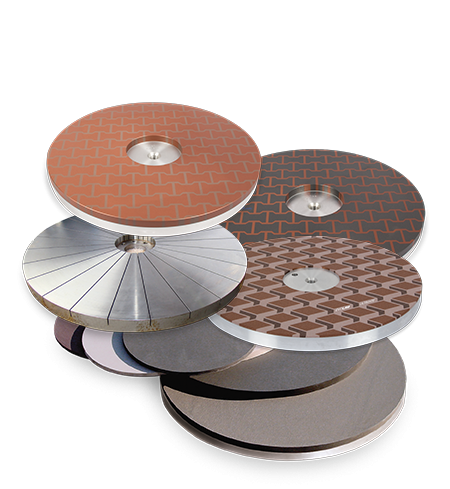

NEW LAM® M’M’ plates

25 years ago, LAM PLAN designed the patented NEW LAM® M’M’ poli-lapping system. Since then LAM PLAN has constantly made its process evolve to respond to the technical requirements of its customers. The system patented and established in production plants throughout the world is today a must in the lapping polishing process.

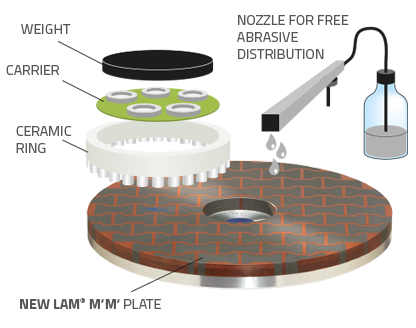

The NEW LAM® M’M’plate, uses free diamond abrasives for its operation. As soon as the plate starts rotating, under the effect of the initial weight of the parts and the load applied by the machine’s jacks, the diamond grains move and fix on the surface of the plate producing a unique abrasive action on the side of the parts to be lapped.

The patent:

The disposition and the shape of the two components of the plate permit an optimum alternation between the hard areas and the soft areas. The cut angle of the diamond grains is permanently changed, which ensures a large stock removal and a perfect inherent flatness.

Fields of application

NEW LAM® M’M’ patented plates BLUE – Rough lapping

| Standard | |||

| Ø |

Thickness (mm) | Ø central bore in mm |

Ref. |

| 14″ 355 mm | 13 | 09 NL103 20 | |

| 15″ 381 mm | 13 | 100 | 09 NL103 30 |

| 16″ 406 mm | 13 | 100 | 09 NL103 40 |

| 19″ 480 mm | 13 | 100 | 09 NL103 55 |

| 24″ 610 mm | 15 | 115 | 09 NL103 60 |

| 27″ 700 mm | 15 | 150 | 09 NL103 70 |

| 30″ 762 mm | 15 | 152 | 09 NL103 80 |

| 36″ 914 mm | 15 | 175 | 09 NL103 90 |

| 1000 mm | 15 | 188 | 09 NL103 00 |

| 1200 mm | 15 | 240 | 09 NL103 50 |

| 1500 mm | 15 | 300 | 09 NL103 10 |

| Incorporated cooling circuit | |||

| Ø |

Thickness (mm) | Ø central bore in mm |

Ref. |

| 15″ 381 mm | 13 | 100 | 09 NL203 30 |

| 24″ 610 mm | 15 | 115 | 09 NL203 60 |

| 700 mm | 15 | 150 | 09 NL203 70 |

| 1000 mm | 15 | 188 | 09 NL203 00 |

| 1200 mm | 15 | 240 | 09 NL203 50 |

| 1500 mm | 15 | 300 | 09 NL203 10 |

NEW LAM® M’M’ patented plates GREEN – Fine Lapping/Polishing

| Standard | |||

| Ø |

Thickness (mm) | Ø central bore in mm |

Ref. |

| 14″ 355 mm | 13 | 09 NL106 20 | |

| 15″ 381 mm | 13 | 100 | 09 NL106 30 |

| 16″ 406 mm | 13 | 100 | 09 NL106 40 |

| 19″ 480 mm | 13 | 100 | 09 NL106 55 |

| 24″ 610 mm | 15 | 115 | 09 NL106 60 |

| 27″ 700 mm | 15 | 150 | 09 NL106 70 |

| 30″ 762 mm | 15 | 152 | 09 NL106 80 |

| 36″ 914 mm | 15 | 175 | 09 NL106 90 |

| 1000 mm | 15 | 188 | 09 NL106 00 |

| 1200 mm | 15 | 240 | 09 NL106 50 |

| 1500 mm | 15 | 300 | 09 NL106 10 |

| Incorporated cooling circuit | |||

| Ø |

Thickness (mm) | Ø central bore in mm |

Ref. |

| 15″ 381 mm | 13 | 100 | 09 NL206 30 |

| 24″ 610 mm | 15 | 115 | 09 NL206 60 |

| 700 mm | 15 | 150 | 09 NL206 70 |

| 1000 mm | 15 | 188 | 09 NL206 00 |

| 1200 mm | 15 | 240 | 09 NL206 50 |

| 1500 mm | 15 | 300 | 09 NL206 10 |

NEW LAM® M’M’ patented plates YELLOW – Super finishing polishing

| Standard | |||

| Ø |

Thickness (mm) | Ø central bore in mm |

Ref. |

| 14″ 355 mm | 13 | 09 NL105 20 | |

| 15″ 381 mm | 13 | 100 | 09 NL105 30 |

| 16″ 406 mm | 13 | 100 | 09 NL105 40 |

| 19″ 480 mm | 13 | 100 | 09 NL105 55 |

| 24″ 610 mm | 15 | 115 | 09 NL105 60 |

| 27″ 700 mm | 15 | 150 | 09 NL105 70 |

| 30″ 762 mm | 15 | 152 | 09 NL105 80 |

| 36″ 914 mm | 15 | 175 | 09 NL105 90 |

| 1000 mm | 15 | 188 | 09 NL105 00 |

| 1200 mm | 15 | 240 | 09 NL105 50 |

| 1500 mm | 15 | 300 | 09 NL105 10 |

| Incorporated cooling circuit | |||

| Ø |

Thickness (mm) | Ø central bore in mm |

Ref. |

| 15″ 381 mm | 13 | 100 | 09 NL205 30 |

| 24″ 610 mm | 15 | 115 | 09 NL205 60 |

| 700 mm | 15 | 150 | 09 NL205 70 |

| 1000 mm | 15 | 188 | 09 NL205 00 |

| 1200 mm | 15 | 240 | 09 NL205 50 |

| 1500 mm | 15 | 300 | 09 NL205 10 |

EVOLAM® composite plates

A plate for 3 steps

The new EVOLAM® ULTIMATE and EVOLAM® CLASSIC lapping plates have been specially developed for hard materials such as sapphire and technical ceramics. The specific composition of these plates gives them an excellent stock removal combined with a low roughness. A poly-lapping operation with our EVOLAM® plates allows to obtain the superfinishing stage in only one step.

A C or H groove is generally made on EVOLAM® plates to increase their performance.

EVOLAM® ULTIMATE composite plates

| Ø |

Thickness | Ref. |

| 15″ 381 mm | 8 mm | 09 EL154 30 |

| 19″ 480 mm | 8 mm | 09 EL154 55 |

| 24″ 610 mm | 8 mm | 09 EL154 60 |

| 700 mm | 8 mm | 09 EL154 70 |

EVOLAM® CLASSIC composite plates

| Ø |

Thickness | Ref. |

| 30’’ 762 mm | 13 mm | 09 EL104 80 |

| 36’’ 914 mm | 13 mm | 09 EL104 90 |

| 1000 mm | 13 mm | 09 EL104 00 |

| 1200 mm | 13 mm | 09 EL104 50 |

| 1500 mm | 13 mm | 09 EL104 10 |

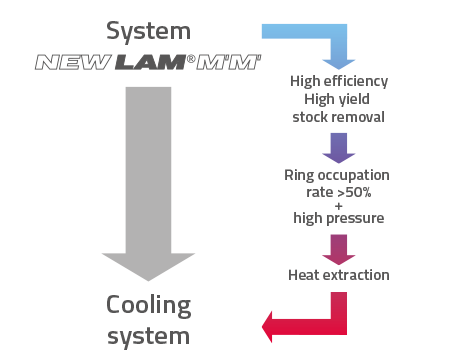

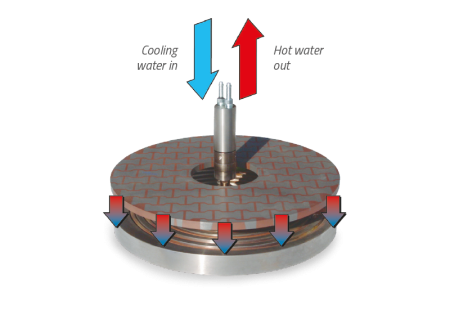

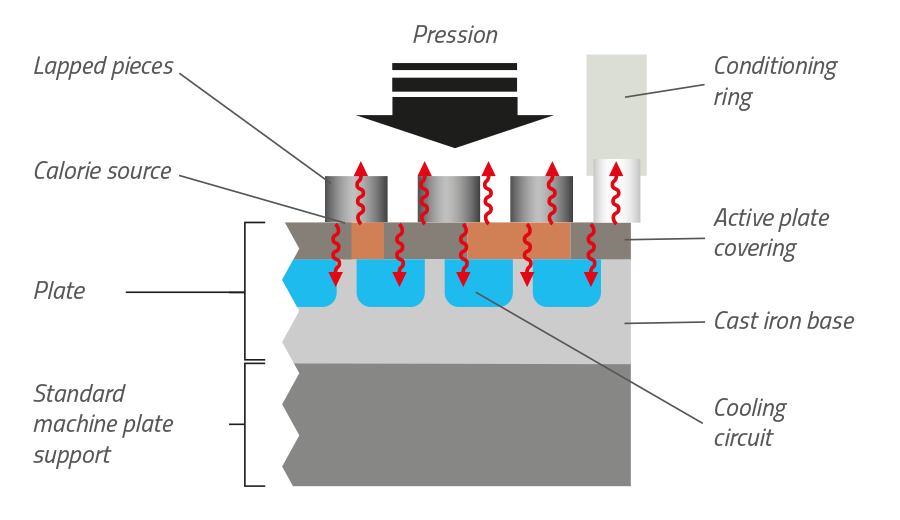

Temperature control system

Flat lapping is based on the laws of mechanics and physics where a constant temperature is essential.

Temperature variations of a lapping plate, whether inherent in the lapping process or dependent on external conditions, can be detrimental to the quality of the desired result. To avoid such damage, the use of our plates at high yield NEW LAM M’M’ requires the use of a temperature control system.

COMPOSITE LAM PLAN plates with an integrated cooling system ensure temperature fluctuation control during series production. This option enables avoidance of plate distortion and consequently, distortion of your pieces.

P803 regulator

To control the flatness of the trays, the temperature must be controlled.

To control plate flatness, temperature must be regulated. The LAM PLAN P803 temperature regulation unit is reversable. It can also raise the plate temperature before use. This enables lapping to start in optimum geometric conditions in any work environment.

The P803 regulator is designed to maintain the temperature between 2 set values. It is an autonomous machine which has its own command interface.

NEW LAM M’M’ plate with temperature regulation system

The LAM PLAN cooling system captures calories directly under the active plate surface. It is adaptable for all machines.

Series 2000 mono-component plates

Primarily used during pre-polishing phases these plates allow a surface condition

which facilitates the finishing step on polishing cloths to be optained.

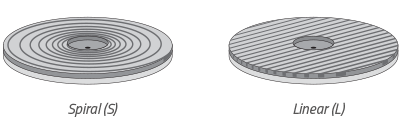

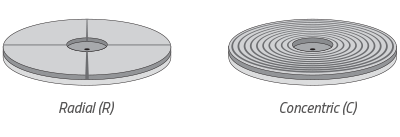

Available in solid version or to order with radial, concentric, spiral or linear grooving.

Different kinds of grooves

2006 mono-component plates

Middle & fine Lapping Polishing – All materials

| For abrasive 6 µm to 1 µm | ||

| Ø |

Thickness (mm) | Ref. |

| 15″ 381 mm | 13 | 09 P2006 30 |

| 19’’ 480 mm | 13 | 09 P2006 55 |

| 24″ 610 mm | 13 | 09 P2006 60 |

| 700 mm | 13 | 09 P2006 70 |

| 1 000 mm | 13 | 09 P2006 00 |

2001 mono-component plates

Fine Lapping – Hard material

| For abrasive 15 µm to 1 µm | ||

| Ø |

Thickness (mm) | Ref. |

| 15″ 381 mm | 6 | 09 P2001 30 |

| 19’’ 480 mm | 6 | 09 P2001 55 |

| 24″ 610 mm | 6 | 09 P2001 60 |

| 700 mm | 6 | 09 P2001 70 |

| 1 000 mm | 6 | 09 P2001 00 |

2002 mono-component plates

Rough Lapping – All materials

| For abrasive 30 µm to 15 µm | ||

| Ø |

Thickness (mm) | Ref. |

| 15″ 381 mm | 13 | 09 P2002 30 |

| 19’’ 480 mm | 13 | 09 P2002 55 |

| 24″ 610 mm | 13 | 09 P2002 60 |

| 700 mm | 13 | 09 P2002 70 |

| 1 000 mm | 13 | 09 P2002 00 |

2003 mono-component plates

Fine Lapping – All materials

| For abrasive 9 µm to 3 µm | ||

| Ø |

Thickness (mm) | Ref. |

| 15″ 381 mm | 13 | 09 P2003 30 |

| 19’’ 480 mm | 13 | 09 P2003 55 |

| 24″ 610 mm | 13 | 09 P2003 60 |

| 700 mm | 13 | 09 P2003 70 |

| 1 000 mm | 13 | 09 P2003 00 |

2005 mono-component plates

Super finishing polishing – All materials

| For abrasive 3 µm to 1 µm | ||

| Ø |

Thickness (mm) | Ref. |

| 15″ 381 mm | 13 | 09 P2005 30 |

| 19’’ 480 mm | 13 | 09 P2005 5 |

| 24″ 610 mm | 13 | 09 P2005 60 |

| 700 mm | 13 | 09 P2005 70 |

| 1 000 mm | 13 | 09 P2005 00 |

2007 mono-component plates

Super finish Polishing – All materials

| For abrasive 2 µm to 1 µm | ||

| Ø |

Thickness (mm) | Ref. |

| 15″ 381 mm | 13 | 09 P2007 30 |

| 19’’ 480 mm | 13 | 09 P2007 55 |

| 24″ 610 mm | 13 | 09 P2007 60 |

| 700 mm | 13 | 09 P2007 70 |

| 1 000 mm | 13 | 09 P2007 00 |

Guidance

Positioning of LAM PLAN composite lapping plates