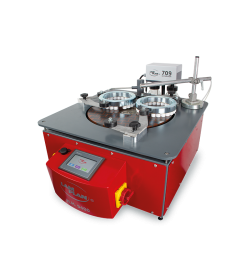

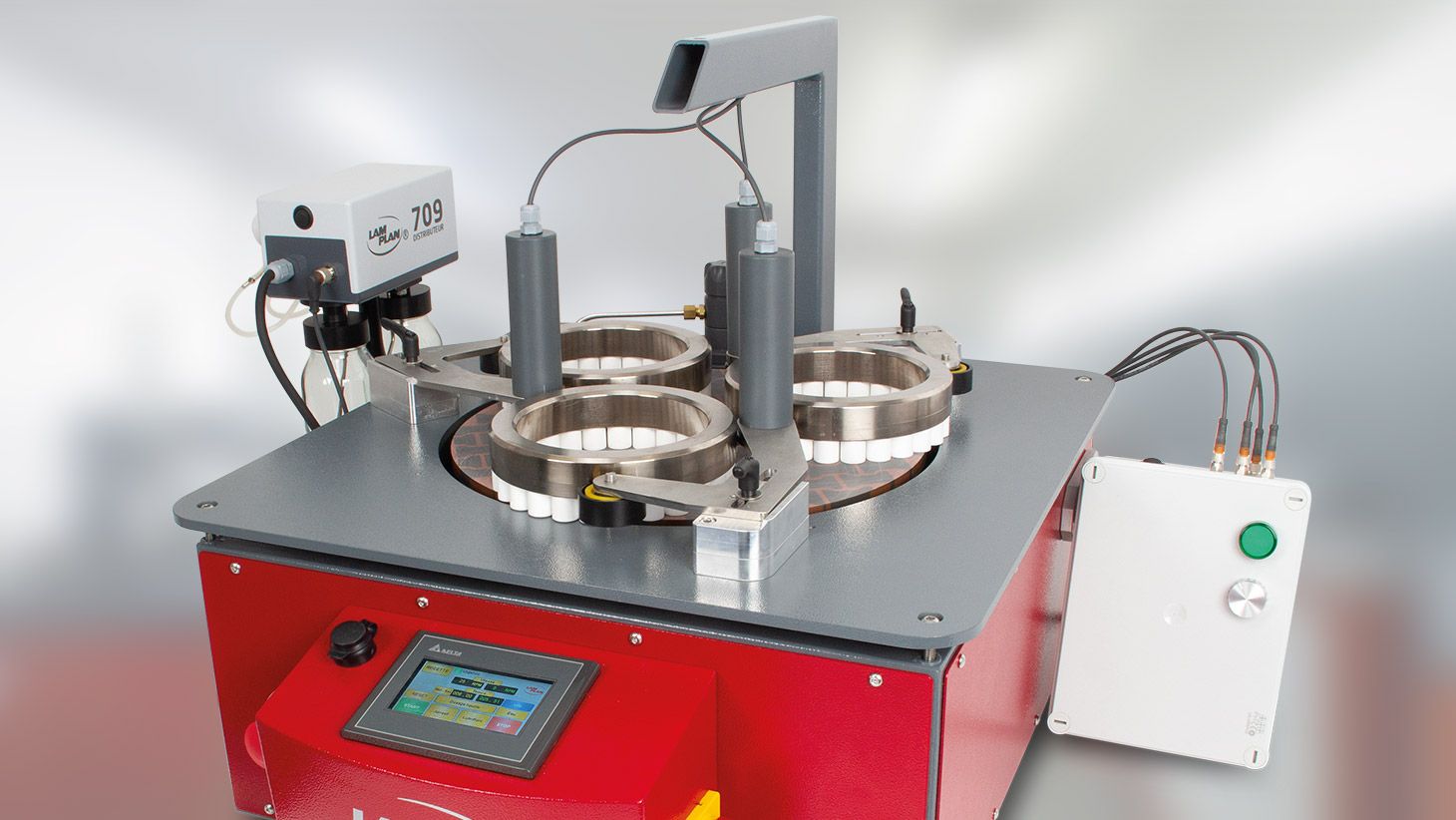

Lapping & polishing machine for variable production of small parts: Ø 5 to 130 mm

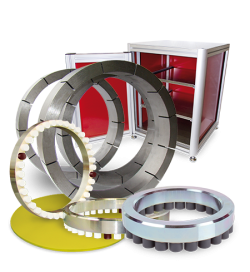

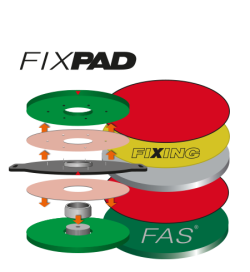

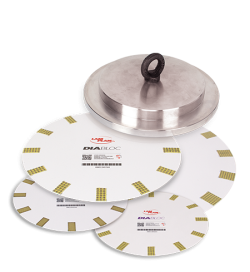

can be fitted with cast iron, DIALAM®, NEW LAM® M’M’ or FAS®

• Programme import/export on USB key,

• Ergonomically improved controls (better visibility of screen in working position),

• Improved connectivity, ability to control 3 dispensers, remote maintenance facility,

• Memory for 30 recipes.

or accessories, such as dosing devices, jib, etc

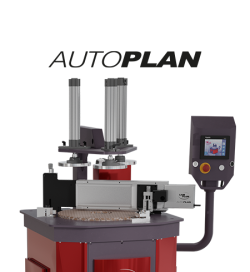

M.M.9400

BASIC SERIES

For this new version of our best-selling M.M.8400, we’ve tried to retain the essence of this table-top trimmer/polisher by making a number of fundamental improvements.

-

Plate Ø381 mm (Ø 400 mm optional)

-

Plate rotation speedfrom 20 to 120 rpm

-

Inner ring Ø140 mm

-

Weight75 kg

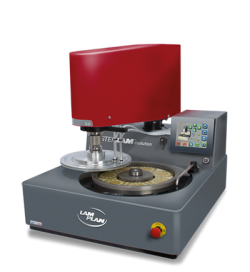

The M.M.9400 is a solution for integrating a means of finishing flat surfaces into your workshop at a contained price. The machine’s compact dimensions and ergonomic controls are still there, but it has become more rigid and even more versatile.

It can be fitted with a wide range of accessories to adapt your equipment to your needs. Integrated control of LAM PLAN feeders, recipe memory and motorised drive are just some of the possibilities.

Versatility

The M.M.9400 can be fitted with cast iron, DIALAM®, NEW LAM® M’M’ or FAS® platens, enabling you to achieve all types of surface finish defined in your specifications (e.g. honing, thickness adjustment, honing, polishing, etc.). It is also perfectly suited to your maintenance needs on all sealing parts (e.g. lapping of flaps, safety valves or small mechanical seals).

New configuration and improvements

- More rigid welded tubular steel chassis, stainless steel tank,

- Ergonomically improved controls (better visibility of screen in working position),

- 4.3’ touch screen,

- Programme import/export on USB key,

- Multiple attachment points for accessories, such as dosing devices, jib, etc,

- Memory for 30 recipes,

- Mobile water inlet controlled by solenoid valve,

- Improved connectivity, ability to control 3 dispensers, remote maintenance facility.

Design and advanced technology

Technical characteristics and equipment

Optional specific equipment

-

E M.M.9400 stem accessory support109 400PA 00

-

Table option Ø 400 mm for M.M.9400*109 400T4 00

-

Support cabinet, height 73 cm, 1 door and 2 shelves10 9400M 00

Downloads

Technical data M.M.9400

Plate Ø | 381 mm (Ø 400 mm optional) |

Inner ring Ø | 140 mm |

Capacity per ring | 1 part Ø130 mm or 170 parts Ø 5 mm |

Number of rings | 3 |

Electric power supply | 230 V single-phase |

Motor Power | 0.75 kW |

Control | 4.3‘’ touch screen |

Plate rotation speed | From 20 to 120 rpm |

Dim. (W x D x H) | 625 x 720 x 365 mm |

Weight (without plate) | 75 kg |

Abrasive distribution system | Optional – see table |

Reference | 10 09400 00 |

*For use with a 400 mm diameter table top, a special table is available as an option.

Available accessories

Special support cabinet M.M.9400

Dedicated, more rigid support cabinet with improved storage capacity (flat storage for trays or discs up to Ø 400 mm, storage for products up to 5-litre drums).

- height 73 cm,

- 1 door

- 2 shelves

E stem

Accessory support

Table option Ø 400 mm for M.M.9400

For use with a 400 mm diameter table top, a special table is available as an option.

Motorised arm kit

Motorised arm: 109 400BM 00

Motorised arm control unit: 109 400UC 00

Compatible with the M.M.9400, 9380 and 9480 machines, the motorised arms are accessories that optimise ring rotation for parts or supports with high adhesion. They are modular kits comprising 1 control unit and 1 to 3 motorised arms, servo-assisted start/stop, speed of rotation adjustable by potentiometer.

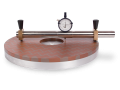

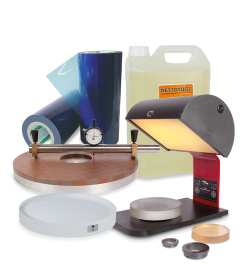

Micrometric gauge

For a fast and precise check of your lapping plates, with a direct reading of the measurements. Precision: 1 µm.

The transport and storage case includes:

- 1 marble, accuracy : 0,8 µm.

- 1 gauge made of stabilised aluminium or stainless steel for machines Ø 200 to 600 mm.

- 1 micron comparator.

- 1 user guide with charts and mapping formulas.

Material removal control MESUREO

MESUREO assembly with storage case

Material removal control, compatible with the M.M.9400, 9380 and 9480 machines, enabling flat surfaces to be obtained to less than one micron, combined with parallelism of less than 5 microns between the lapped face and a reference.

The MESUREO consists of a perfectly flat ceramic-coated pressure disc that moves on a vertical axis.

This tool is equipped with a wireless probe, enabling the removal of material to be displayed in real time on a PC placed close to the lapping machine. The target dimension can be set. Using a highly intuitive set of colours, the operator can quickly see on his computer monitor whether the parts are within the defined thickness tolerance.

Temperature control system P803

Flat lapping is based on the laws of mechanics and physics where a constant temperature is essential.

To control plate flatness, temperature must be regulated. The LAM PLAN P803 temperature regulation unit is reversable. It can also raise the plate temperature before use. This enables lapping to start in optimum geometric conditions in any work environment.

The P803 regulator is designed to maintain the temperature between 2 set values. It is an autonomous machine which has its own command interface.

Dedicated dosing units

Peristaltic and venturi dosing units 709, 710 and 719

This series of dispensers is fitted to LAM PLAN lapping machines. They are controlled from the machine interface and are fully integrated into the programming cycles. The different models can be used to dispense all types of products.

Peristaltic and vortex mixing dispensers 8017, 8003 and 8007

These dispensing systems are suitable for any type of abrasive immersed in a liquid. They solve the problem of settling and guarantee regular and guarantee regular, repeatable results.