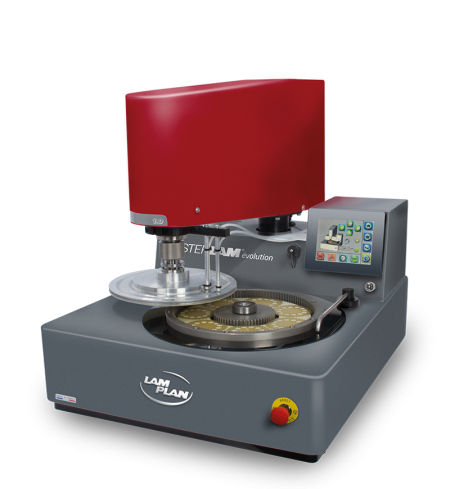

MASTERLAM ®Evolution

In order to answer to double-side polishing issues in small series or development phase, LAM PLAN proposes the MASTERLAM® Evolution, an original and innovating approach for double-side polishing.

-

Plate CapacityØ 250 mm ext.

Ø 130 mm int. -

Useful capacity7 satellites Ø 65 mm

-

Plates rotational speed20-150 rpm Bidirectional

-

Weight95 kg

The MASTERLAM® Evolution is a compact and economical solution for double-side polishing, to realise high quality polishing on any kind of small parts. This equipment is particularly well-

adjusted for the finishing of watch components in small series, pre-series or prototyping.

Description

The MASTERLAM® Evolution is based on a simple kinematic proposing 2 movements: clock-wise or anti-clockwise rotation of the superior plate and the main cogwheel with speed programming. These 2 movements will allow you to respond to most of your needs in terms of polishing of small series of all types of materials.

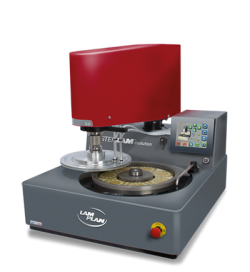

Touch screen control panel

The 5.7 inches’ touch screen in this machine will enable you to manage all the settings: cycle time, rotational speed, rotation movement, pressure during cycle and abrasives distribution sequences. This intuitive screen is also offering you the possibility to save more than 300 operating ranges. A water rinse phase is also possible at the end of the cycle.

A well-equipped and safe machine

The MASTERLAM® Evolution outer ring gear is made of 316 L stainless steel, assuring a durability of the moving parts.

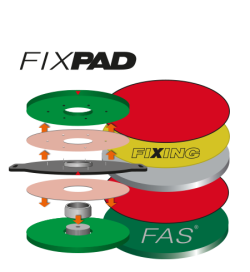

The machine is also equipped with two FAS® plates facilitating the setting up of the polishing cloths.

Design and advanced technology

Technical characteristics and equipment

Downloads

MASTERLAM® Evolution data sheet

Plate Capacity | 7 carriers track Ø 250 mm ext. Ø 130 mm int. |

Useful capacity | 7 satellites Ø 65 mm |

Superior plate rotational speed | 20 to 150 rpm Bidirectional rotation |

Cogwheel rotational speed | 20 to 150 rpm Bidirectional rotation |

Cogwheel motor power | 0.75 kW |

Superior plate motor power | 0.2 kW |

Pressure | 5 to 400 N |

Required energies | 230 V-50 Hz single-phase Compressed air 6 bars filtered 10 µm |

Total power | 2.5 kW |

Noise level | < 80 db at 1 metre away |

Dim. (W x H x D) | 550 x 670 x 580 mm |

Weight | 95 kg |

Reference | 60ML1EVO00 |

Available accessories

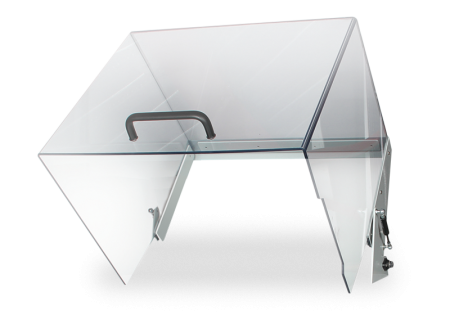

Transparent protective housing

The secured housing is a totally transparent protection compatible with the full range of MASTERLAM®.

Its opening stops all movements of the machine*, it offers

an integral protection complying with the 2006/42/ CE and 2004/108/CE standards. The housing’s design preserves the accessibility of the plate and does not clutter the workspace.

The touch screen is located outside of the secured zone; therefore, the commands are permanently accessible.

For the MASTERLAM®Evolution, the touch screen control panel is located on the right, a 195 mm space needs to be foreseen in addition to the machine width.

*However, the transparent secured housing authorises the plate rotation in the manual mode.

Required space for the MASTERLAM® Evolution :

Width 770 mm – Height 910 mm.

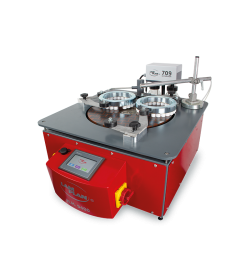

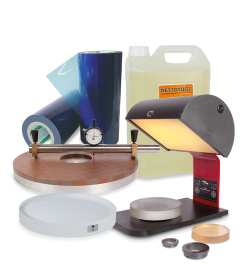

Automatic dispensers

The DISTRILAM® automatic dispenser is controlled directly from the machine screen via a connector. It is instantly recognised by all MASTERLAM® polishing machines. The dispenser is equipped with 4 independent circuits consisting of 3 standard peristaltic pumps for precise dosing of diamond liquids and 1 higher flow peristaltic pump for dosing lubricant or colloidal abrasive. It operates without compressed air or electrical connection. The DISTRILAM® automatic dispenser is an essential accessory for automated use of MASTERLAM®.

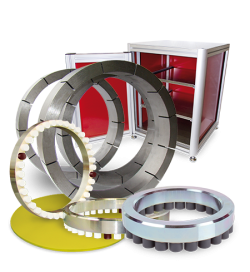

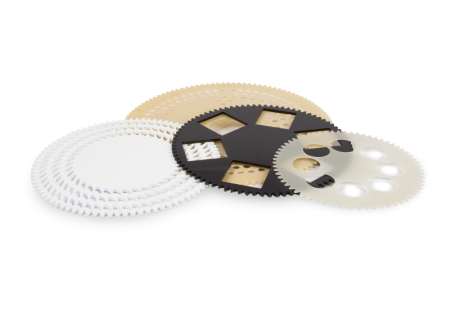

Carriers for double-sided machines

The carriers are used to maintain the parts on the double-side machine. Their conception is realised according to the geometry of your parts or according to your drawings. Our carriers are available in a wide range of thickness, from a few millimetres to 200 µm.

Depending on your application and the nature of your parts, we propose our carriers in a large range of materials, such as stainless steel, blue steel (hardened until 600 Hv), glass fibre, aramid, PVC, epoxy,… For any double-side machine brand.