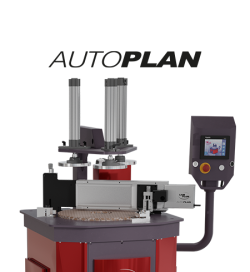

M.M.2380

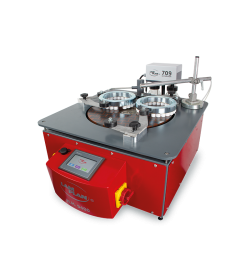

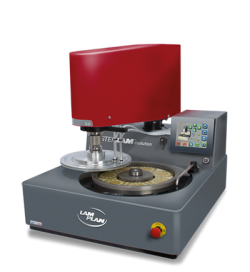

Reliable, optimised solution for double-sided honing and polishing.

-

Plate CapacityØ 380 mm ext.

Ø 153 mm int. -

Useful capacity5 satellites Ø 125 mm

-

Plate rotational speed0 to 120 rpm bidirectional

-

Weight750 kg

M.M.2380 new version, what’s new:

- You can save 96 recipes, each containing 5 sub-steps,

- Cooling the sequenced plate,

- Cleaning shower,

- End of cycle detachment’ programme,

- Password-protected access, import/export of recipes on USB stick in CSV format,

- Remote maintenance (connection required).

The plates (top and bottom) and central pinion are driven by brushless motors. This means that speeds and directions of rotation can be varied. The plates have an external diameter of 380 mm and can accommodate 5 satellites (useful capacity Ø 125 mm).

Stable, reproducible results cycle after cycle

Developed on the basis of tried-and-tested technology, this optimised version is the perfect answer to your lapping or double-sided polishing requirements for production workpieces with diameters of between 5 and 30 mm.

The M.M.2380 can be fitted with LAM PLAN lapping plates, making it ideal for applications where precise geometry and dimensions are key criteria.

In addition, the possibility of combining the M.M.2380 with the TOUCHLAM® range of polishing surfaces will meet the demands of the watchmaking or optical sectors where a polished surface finish is the main criterion.

10.5’ touch screen control interface

The architecture of the man-machine interface means that the equipment can be operated very quickly. This screen will display, among other things, the pressure applied to the parts and the motor torques in real time.

Stop quote

The M.M.2380 is equipped with a ‘stop-cote’ device. Irrespective of the cycle time, the machine automatically stops its cycle when the target workpiece thickness is reached.

Design and advanced technology

Technical characteristics and equipment

Production support accessories

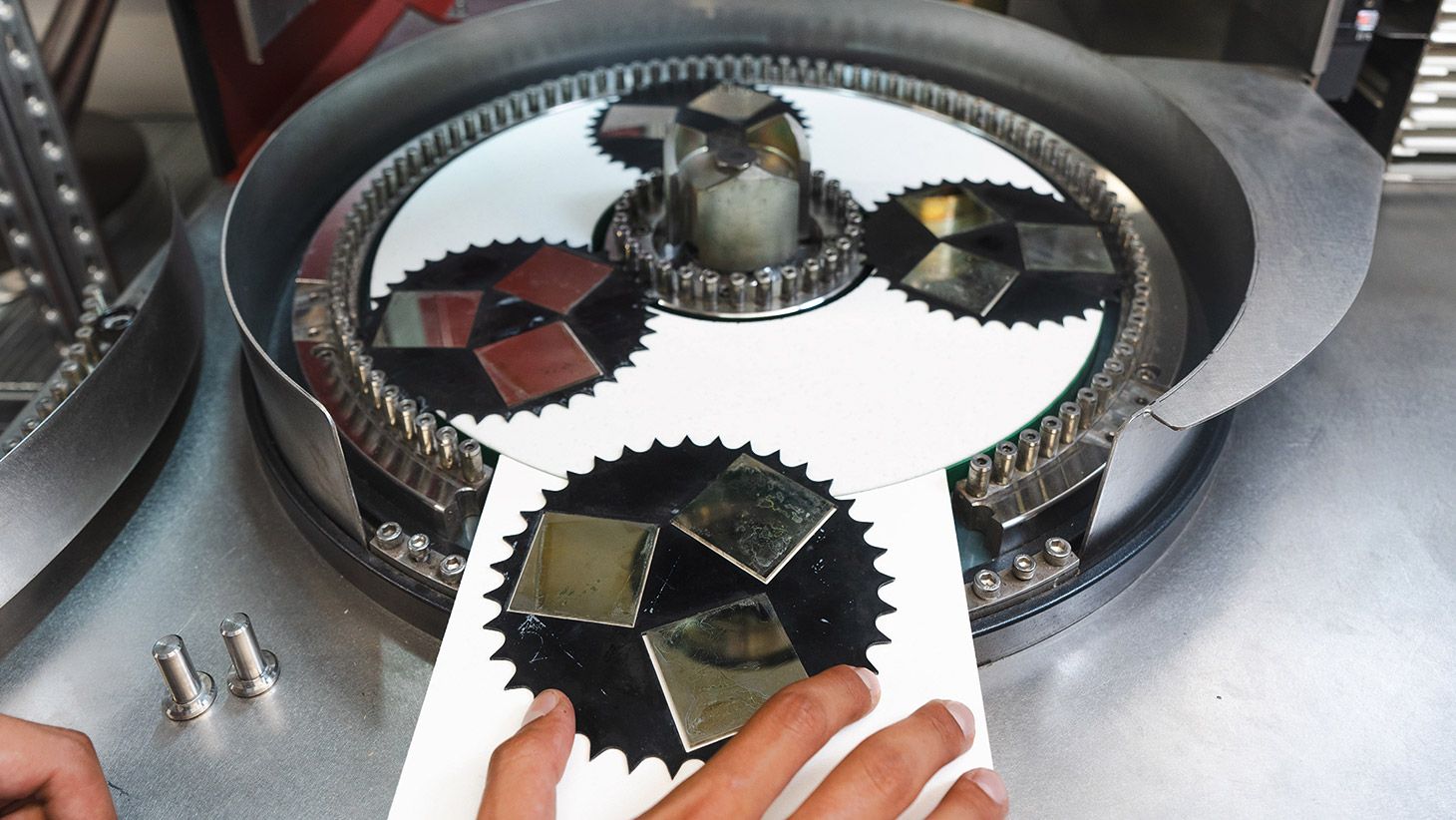

The M.M.2380 can be fitted with a solution for the rapid positioning of workpiece-carrying satellites. A ‘rack’ system can be used to store several satellites loaded by the operator in hidden time. The machine’s gear ring has a removable part. When the polishing phase is complete, the operator can move the satellites and retrieve them directly from a magnetic shelf provided for this purpose. Conversely, the satellites (pre-filled with parts) can be loaded into the machine (to restart a new cycle) in the same way.

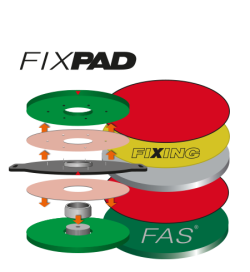

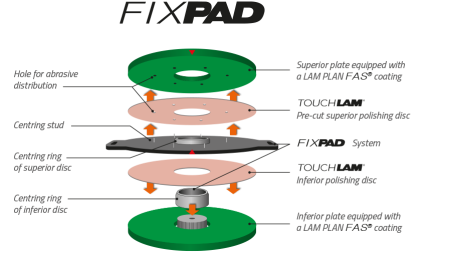

The FIXPAD® system combined with the FAS® plate will make it much easier to change polishing supports and adjust the fluid injection holes.

Accessories for M.M.2380

-

M.M.2380 flatness control gauge08 00898 10

-

Cast iron plate Ø 380 Ra15x15V0 15RID BL

-

Cast iron plate Ø 380 Ra15x15V0 15RSD BL

-

Cast iron plate inf Ø 380 40R radV0 15RID BM

-

Cast iron plate Ø 380 40R radV0 15RSD BM

-

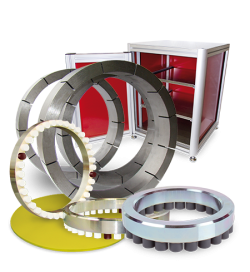

Toothed stainless steel central sprocket10 1008 35

-

Stainless steel external crown with sect. teeth10 1008 30

-

External toothed stainless steel crown10 1008 32

-

FAS inf plate Ø 380 mm H 152 mm09 FASINDP 400

-

FAS sup plate Ø 380 mm H 152 mm09 FASSUDP 400

-

Satellite cast iron 66 Dents Rainu10 1008 65

-

Satellite download system09 2380DE 10

-

Satellite unloading system09 2380DE 20

-

Tablet S satellite download09 2380DE 30

-

Stainless steel external crown with Sect pins10 1008 40

-

Stainless steel central pinion10 1008 45

M.M.2380 data sheet

Plate Capacity | 5 carriers track Ø 380 mm ext. / Ø 153 mm int. |

Useful capacity | 5 satellites Ø 125 mm |

Plate rotation speed | 0 to 120 rpm |

Pinion speed | 0 to 80 rpm Bidirectional rotation |

Plate and pinion motor power | 0.75 kW for each motor |

Energy required | 400 V-50 Hz three-phase + neutral. Compressed air 6 bars filtered 10 µm |

Cumulative power | 2.5 kW |

Noise level | < 80 dB at 1 meter away |

Dimensions W x H x D (mm) | 960 x 2030 x 780 mm Working table height 1040 |

Weight | 750 kg |

Reference | 10 23800 00 |

Downloads

Available accessories

FIXPAD® is a tool that allows simple and fast positioning of polishing discs on the plates of double-side machines.

Developed by LAM PLAN, FIXPAD® allows you to stick the discs to the plate without trapping air bubbles and without folds. Due to its design and thanks to the pre-cut TOUCHLAM® discs, the installation of discs on the upper plates is carried out in just seconds. The FIXPAD® pins guide the positioning of the pad when inserted in the distribution holes of the upper plate. This tool will simplify the installation of polishing pads and will limit machine stoppage time.

Peristaltic and vortex mixing dispensers 8017, 8003 and 8007

These dispensing systems are suitable for any type of abrasive immersed in a liquid. They solve the problem of settling and guarantee regular and guarantee regular, repeatable results.

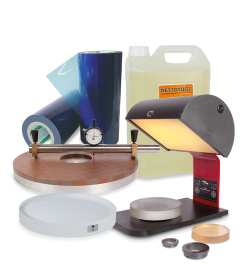

For a fast and precise check of your lapping plates, with a direct reading of the measurements.

Precision: 1 µm.

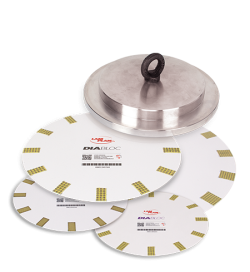

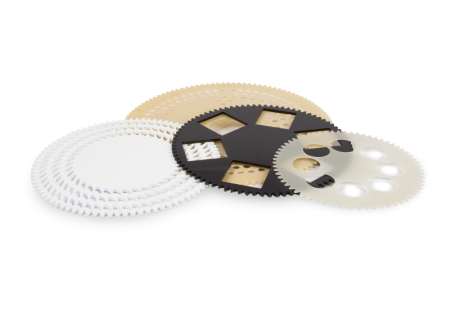

The carriers are used to maintain the parts on the double-side machine. Their conception is realised according to the geometry of your parts or according to your drawings. Our carriers are available in a wide range of thickness, from a few millimetres to 200 µm.

Depending on your application and the nature of your parts, we propose our carriers in a large range of materials, such as stainless steel, blue steel (hardened until 600 Hv), glass fibre, aramid, PVC, epoxy,… For any double-side machine brand.