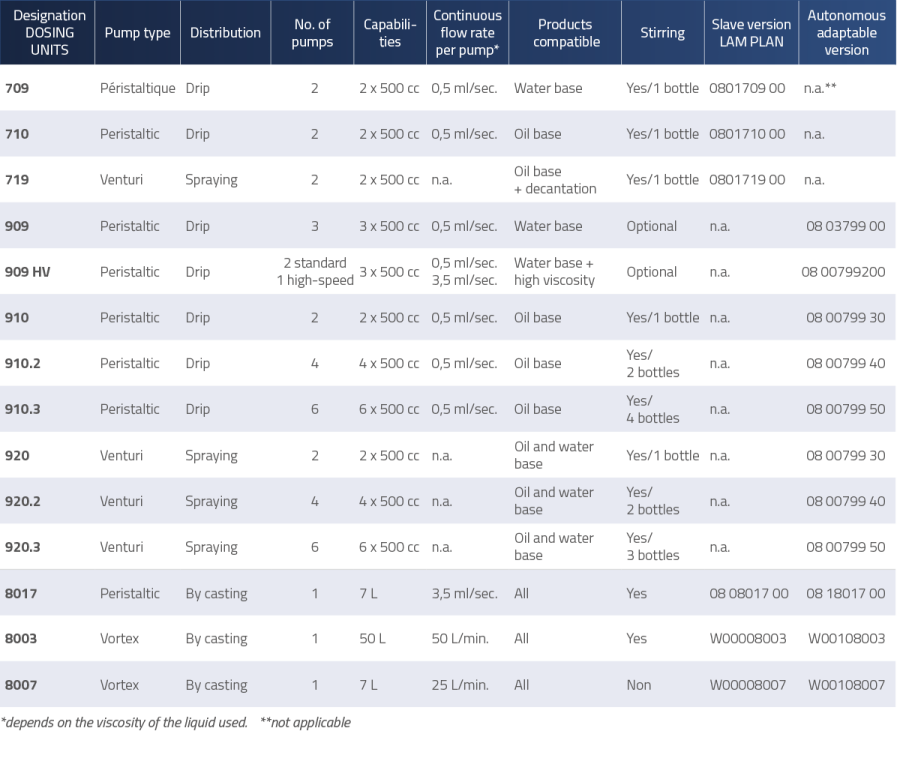

Dosing units, mixing distributors and nozzles

For AQUA LAM®, M.M. & diamond liquids

Automated dosing

Automated dosing ensures precise, even product distribution. This is the solution for controlling the abrasive film and lubrication. Material removal performance and temperature control depend directly on the quality and consistency of the abrasive film.

Different settings, distribution intervals, spraying times and nozzle positioning ensure consistent, reproducible polishing results and savings on consumables.

A dosing solution for every product and every application.

The venturi system is reserved for products with low viscosity and high settling rates, such as certain oil bases. The peristaltic system is more versatile and has the advantage of not generating mist.

The large-capacity dispensers in the 8000 series are based on vortex pump systems for models 8003 and 8007, and high-flow peristaltic pumps for model 8017. These different models are suitable for the large product distributions generally required by production applications. They are mainly reserved for abrasives from the SiC family, which have a strong tendency to settle.

Dedicated dosing units for LAM PLAN machines

This series of dispensers is fitted to LAM PLAN lapping machines. They are controlled from the machine interface and are fully integrated into the programming cycles.

The different models can be used to dispense all types of products.

The range of nozzles available covers all machine diameters LAM PLAN.

Recommendations for products/machines/dosing devices/nozzles, see tables at the bottom of the page.

Dosing unit 709 – Peristaltic

08 01709 00

Peristaltic model for water-based abrasives.

- Capacity: 2 x 500 cc

- Pump: 2

- Pump flow rate: 0,5 ml/sec.

- Stirrer: 1

- Distribution system: nozzles not included, see machine recommendation.

- Electric power supply: 220V single-phase + 24V control input.

Consumables for 709

| Designation |

Ref. |

| Versitec silicone hose Ø 5-3 per meter – Water base | 60 00271 90 |

| Peristaltic pump body standard model | 60 00667 90 |

| Stirring paddle for dosing unit | 08 00124 90 |

| Level sensor option for diamond liquid and lubricant | 08 90001 00 |

Dosing unit 710 – Peristaltic

08 01710 00

Peristaltic model for OIL-BASED and EMULSION abrasives – High-capacity pumps.

- Capacity: 2 x 500 cc

- Pump: 2 – large-capacity type

- Pump flow rate: 3,5 ml/sec.

- Stirrer: 1

- Distribution system: Nozzles not included, see machine recommendation.

- Electric power supply: 220V single-phase + 24V control input.

Consumables for 710

| Designation |

Ref. |

| Hose Ø 7-3,2 Yellow for – Oil base – Emulsion base – Sold by the metre | 08 1050 10 |

| Peristaltic Pump for M.M.710 | 08 1050 07 |

| Stirring paddle for dosing unit | 08 00124 90 |

|

Level sensor option for diamond liquid and lubricant |

08 90001 00 |

Dosing unit 719 – Venturi

08 01719 00

Venturi model for OIL-BASED and EMULSION abrasives with settling tendency.

- Capacity: 2 x 500 cc

- Venturi: 2

- Pump flow rate: n.a.

- Stirrer: 1

- Distribution system: Nozzles not included, see machine recommendation.

- Electric power supply: 220V single-phase + 24V control input.

Consumables for 719

| Designation |

Ref. |

| Flexible Crystal Hose Ø 6-3 (venturi) per meter – Oil and water base | 60 00270 90 |

| Stirring paddle for dosing unit | 08 00124 90 |

| Level sensor option for diamond liquid and lubricant | 08 90001 00 |

Compact stand-alone dosing units

The 909 and 909HV compact stand-alone dosing units make it easy to equip small capacity machines with a high-performance dosing system. Their compact size makes them ideal for retrofitting equipment. They are designed for dispensing water-based abrasives with low decantation.

The possibility of connecting one or 2 stirrers (optional) extends the range of uses for these devices.

Recommended for machines from Ø 380 to 700 mm.

Recommendations for products/machines/dosing devices/nozzles, see tables at the bottom of the page.

Dosing unit 909 – Peristaltic

08 03799 00

Water-based abrasive model.

- Capacity: 3 x 500 cc

- Pump: 3 standard peristaltic pumps

- Pump flow rate: 0,5 ml/sec.

- Drain function: yes – by flow inversion

- Distribution system: Nozzles not included, see machine recommendation.

- Electric power supply: 220V single-phase – 50 Hz

- Communication dosing unit and machine: 1 24 V input for machine control.

- Agitator option: Up to 2 agitators can be added per dosing unit. This helps to manage settling issues in the liquid bottle.

Consumables for 909

| Designation |

Ref. |

| Versitec silicone hose Ø 5-3 per meter – Water base | 60 00271 90 |

| Versitec silicone hose Ø 7-4 per metre | 60 00272 90 |

| Peristaltic pump body standard model | 60 00667 90 |

| Stirring paddle for dosing unit | 08 00124 90 |

| Option 1 stirrer for 500 cc glass bottle | 08 02816 00 |

Dosing unit 909 HV – Peristaltic

08 007992 00

Model equipped with 2 standard pumps and a high-flow pump recommended for high-viscosity abrasive liquids, can be used for small quantities of SiC abrasive.

- Capacity: 3 x 500 cc

- Pump: 2 standard peristaltic pumps 1 high-flow peristaltic for high-viscosity liquids.

- Pump flow rate: 0,5 ml/sec. / 3,5 ml/sec.

- Drain function: yes – by flow inversion

- Distribution system: Nozzles not included, see machine recommendation.

- Electric power supply: 220V single-phase – 50 Hz

- Communication dosing unit and machine: 1 24 V input for machine control.

- Agitator option: Up to 2 agitators can be added per dosing unit. This helps to manage settling issues in the liquid bottle.

Consumables for 909 HV

| Designation |

Ref. |

| Versitec silicone hose Ø 5-3 per meter – Water base | 60 00271 90 |

| Versitec silicone hose Ø 7-4 per metre | 60 00272 90 |

| HV peristaltic pump body | 60 00893 90 |

| Stirring paddle for dosing unit | 08 00124 90 |

| Option 1 stirrer for 500 cc glass bottle | 08 02816 00 |

Modular stand-alone automated dosing units

With TYPE 910 peristaltic dosing units for oil-based diamond abrasives with low decantation and TYPE 920 venturi dosing units for oil- and water-based diamond abrasives with high decantation, you can equip all types of machine with an autonomous, modular and programmable dosing system.

The separate control unit allows the positioning of the module(s) to be adapted to the machine configuration.

Recommendations for products/machines/dosing devices/nozzles, see tables at the bottom of the page.

Dosing unit 910 – Peristaltic

08 MM910A 00

Models for low-settling OIL-BASED abrasives.

For machines from Ø 380 to 700 mm

- Capacity: 2 x 500 cc

- Pump: 2 – large capacity type

- Stirrer: 1

- Drain function: no

- Electric power supply: 220V single-phase – 50 Hz

- Communication dosing unit and machine: 1 24 V input for machine control.

- Distribution system: Nozzles not included, see machine recommendation.

Dosing unit 910.2 – Peristaltic

08 MM910A 20

Models for low-settling OIL-BASED abrasives.

For machines from Ø 762 to 1000 mm

- Capacity: 4 x 500 cc

- Pump: 4 – large-capacity type

- Stirrer: 2

- Drain function: no

- Electric power supply: 220V single-phase – 50 Hz

- Communication dosing unit and machine: 1 24 V input for machine control.

- Distribution system: Nozzles not included, see machine recommendation.

Dosing unit 910.3 – Peristaltic

08 MM910A 30

Models for low-settling OIL-BASED abrasives.

For machines from Ø 1200 to 1500 mm

- Capacity: 6 x 500 cc

- Pump: 6 – large-capacity type

- Stirrer: 3

- Drain function: no

- Electric power supply: 220V single-phase – 50 Hz

- Communication dosing unit and machine: 1 24 V input for machine control.

- Distribution system: Nozzles not included, see machine recommendation.

Dosing unit 920 – Venturi

08 MM920A 00

Models for high-settling OIL-BASED and WATER-BASED abrasives.

For machines from Ø 380 to 700 mm

- Capacity: 2 x 500 cc

- Venturi: 2

- Stirrer: 1

- Drain function: yes

- Electric power supply: 220V single-phase – 50 Hz

- Communication dosing unit and machine: 1 24 V input for machine control

- Distribution system: nozzles not included, see machine recommendation..

Consumables for 920

| Designation |

Ref. |

| Flexible Crystal Hose Ø 6-3 (venturi) per meter – Oil and water base | 60 00270 90 |

| Stirring paddle for dosing unit | 08 00124 90 |

Dosing unit 920.2 – Venturi

08 MM920A 20

Models for high-settling OIL-BASED and WATER-BASED abrasives.

For machines from Ø 762 to 1000 mm

- Capacity: 4 x 500 cc

- Venturi: 4

- Stirrer: 2

- Drain function: yes

- Electric power supply: 220V single-phase – 50 Hz

- Communication dosing unit and machine: 1 24 V input for machine control

- Distribution system: nozzles not included, see machine recommendation..

Consumables for 920

| Designation |

Ref. |

| Flexible Crystal Hose Ø 6-3 (venturi) per meter – Oil and water base | 60 00270 90 |

| Stirring paddle for dosing unit | 08 00124 90 |

Dosing unit 920.3 – Venturi

08 MM920A 30

Models for high-settling OIL-BASED and WATER-BASED abrasives.

For machines from Ø 1200 to 1500 mm

- Capacity: 6 x 500 cc

- Venturi: 6

- Stirrer: 3

- Drain function: yes

- Electric power supply: 220V single-phase – 50 Hz

- Communication dosing unit and machine: 1 24 V input for machine control

- Distribution system: nozzles not included, see machine recommendation..

Consumables for 920

| Designation |

Ref. |

| Flexible Crystal Hose Ø 6-3 (venturi) per meter – Oil and water base | 60 00270 90 |

| Stirring paddle for dosing unit | 08 00124 90 |

Dosing pumps

These dispensing systems are suitable for any type of abrasive immersed in a liquid. They solve the problem of settling and guarantee regular and guarantee regular, repeatable

results. Contact us if you would like to link the dosing unit/pum to your honing machine.

Recommendations for products/machines/dosing devices/nozzles, see tables at the bottom of the page.

Dosing pump 8003

Model for ALL TYPES OF ABRASIVES dispensed in large quantities, controlled by the machine interface or by an integrated sequencer for the autonomous version.

- Capacity: 50 liters capacity with drain valve

- Pump: 1 vortex type

- Pump flow rate: 50 liters/minute

- Stirrer: Yes – variable speed paddle mixer

- Drain function: yes

- Distribution system: 3-way adjustable outlet. 3-way solenoid valve

- Dimensions: H 870 mm X floor Ø 600 mm

- Electric power supply: 220V single-phase – 50 Hz

- Communication dosing unit and machine: 1 24 V input for machine control

| Designation |

Qty | Capacity | Ref. |

| Dosing pump 8003, slave version for LAM PLAN machine | 1 | 50 litres | W000 08003 |

| Dosing pump 8003, autonomous version | 1 | 50 litres | W001 08003 |

| Low abrasive warning system for 9000 series machines | 1 | – | 08 90002 00 |

Distribution system for dosing unit type 8003 and 8007.

Dosing pump 8007

Model for ALL TYPES OF ABRASIVES dispensed in large quantities, controlled by the machine interface or by an integrated sequencer for the autonomous version.

- Capacity: useful tank volume 7 liters

- Pump: 1 vortex type

- Pump flow rate: 25 liters/minute

- Stirrer: no

- Distribution system: 3-way adjustable outlet. 3-way solenoid valve

- Dimensions: H 420 mm X floor Ø 250 mm

- Electric power supply: 220V single-phase – 50 Hz

- Communication dosing unit and machine: 1 24 V input for machine control.

| Designation |

Qty | Capacity | Ref. |

| Dosing pump 8007, slave version for LAM PLAN machine | 1 | 25 liters | W000 08007 |

| Dosing pump 8007, autonomous version | 1 | 25 liters | W001 08007 |

| Low abrasive warning system for 9000 series machines | 1 | – | 08 90002 00 |

Distribution system for dosing unit type 8003 and 8007.

Dosing pump 8017

Model for ALL TYPES OF ABRASIVE. Controlled by the machine interface or by an integrated sequencer for the stand-alone version.

- Capacity: useful tank volume 7 liters

- Pump: 1 peristaltic

- Pump flow rate: 3,5 ml/sec.

- Stirrer: yes – paddle mixer

- Distribution system: Nozzle 813 on mobile stand sold separately

- Dimensions: H 430 mm X floor Ø 250 mm

- Electric power supply: 220V single-phase – 50 Hz

- Communication dosing unit and machine: 1 24 V input for machine control.

| Designation |

Qty | Capacity | Ref. |

| Dosing pump 8017, slave version for LAM PLAN machine | 1 | 7 liters | 08 08017 00 |

| Dosing pump 8017, autonomous version | 1 | 7 liters | 08 18017 00 |

Consumables for 8017

| Designation |

Ref. |

| HV peristaltic pump body – Water base | 60 00893 90 |

| Versitec silicone hose Ø 7-4 per meter | 60 00272 90 |

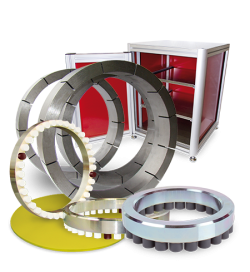

Nozzles for dosing units

Recommendations for products/machines/dosing devices/nozzles, see tables at the bottom of the page.

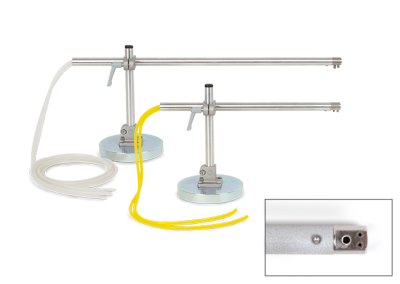

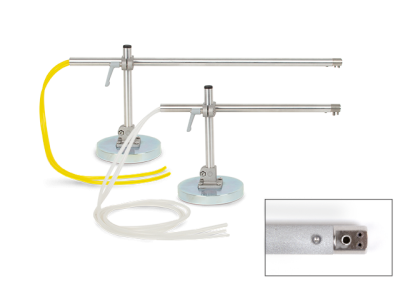

Nozzles 811 for peristaltic dosing pumps

| Designation |

Lapping machine | Product | Ref. |

| 811 | Ø 381 to 700 mm | Water base | 08 00811 00 |

| 811 L | Ø 910 to 1500 mm | Water base | 08 00811 10 |

| 811 H | Ø 381 to 700 mm | Oil and emulsion bases | 08 00811 40 |

| 811 LH | Ø 910 to 1500 mm | Oil and emulsion bases | 08 00811 20 |

Nozzles 813 for peristaltic dosing pumps

| Designation |

Lapping machine | Product | Ref. |

| 813 | Ø 381 to 700 mm | Water base | 08 00813 00 |

| 813 L | Ø 910 to 1500 mm | Water base | 08 00813 10 |

| 813 H | Ø 381 to 700 mm | Oil and emulsion bases | 08 00813 20 |

| 813 LH | Ø 910 to 1500 mm | Oil and emulsion bases | 08 00813 40 |

Nozzles 815 for venturi dosing pumps

| Designation |

Lapping machine |

Product | Ref. |

| 815 | Ø 381 to 700 mm | All bases | 08 00815 20 |

| 815 L | Ø 910 to 1500 mm | All bases | 08 00815 40 |

| 815 XL | Ø 1200 to 1500 mm | All bases | 08 00815 60 |

Glass bottles

Glass bottles

| Designation |

Qty | Ref. | |

| Glass bottle | 2 | 500 cc | 08 02804 00 |

| Glass bottle / stopper / tube | 3 | For 909 and 909 HV | 08 01804 00 |

Dosing units, dispensers, recommendations and compatibility