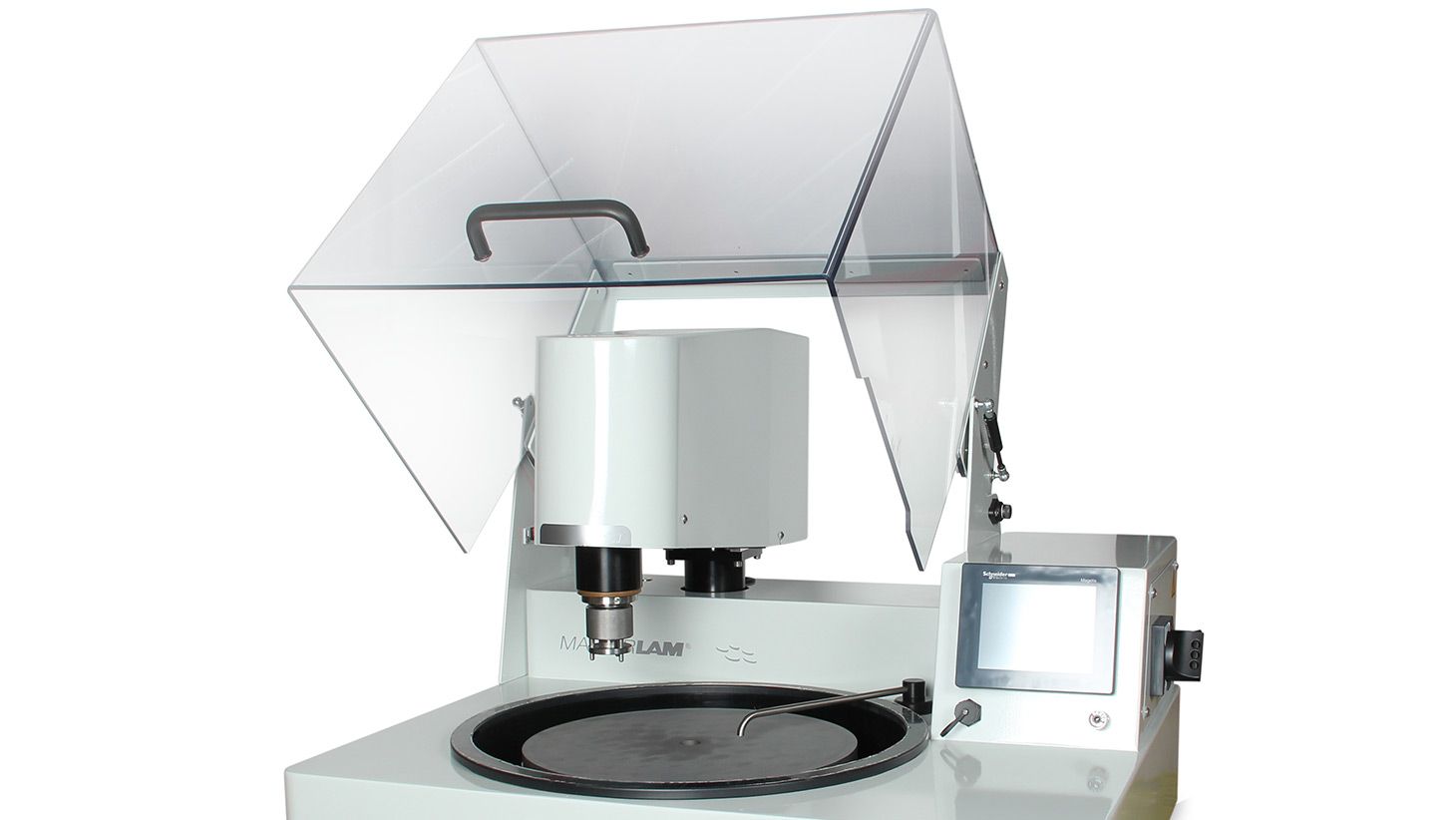

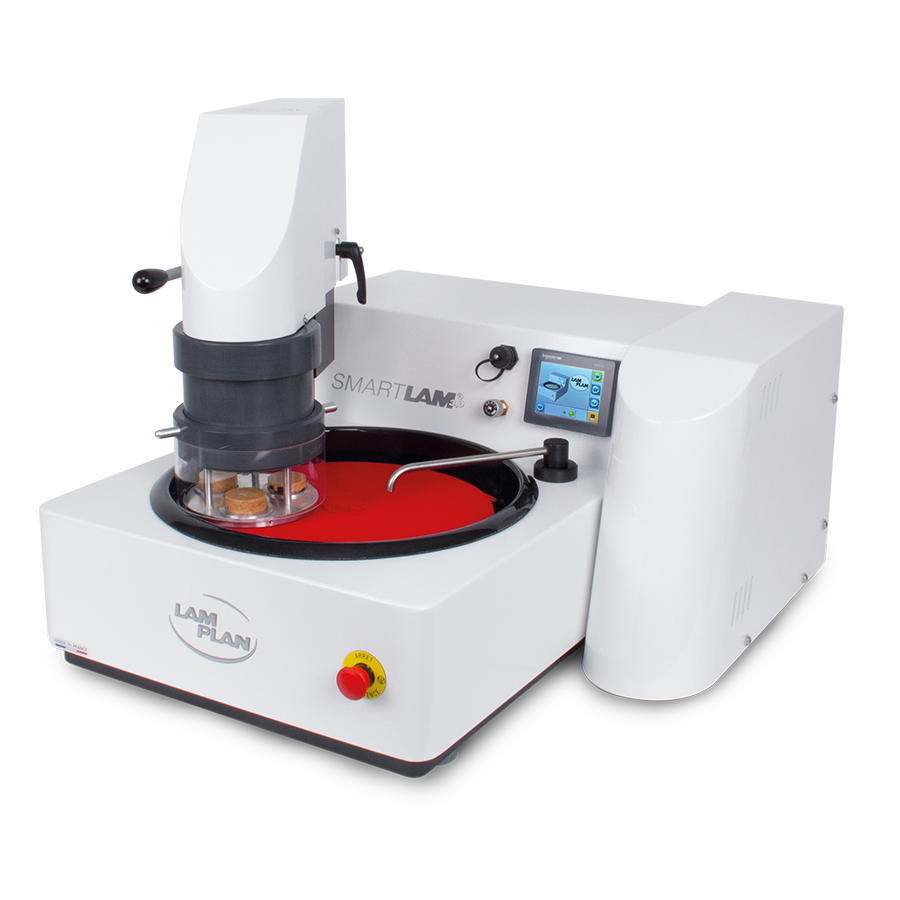

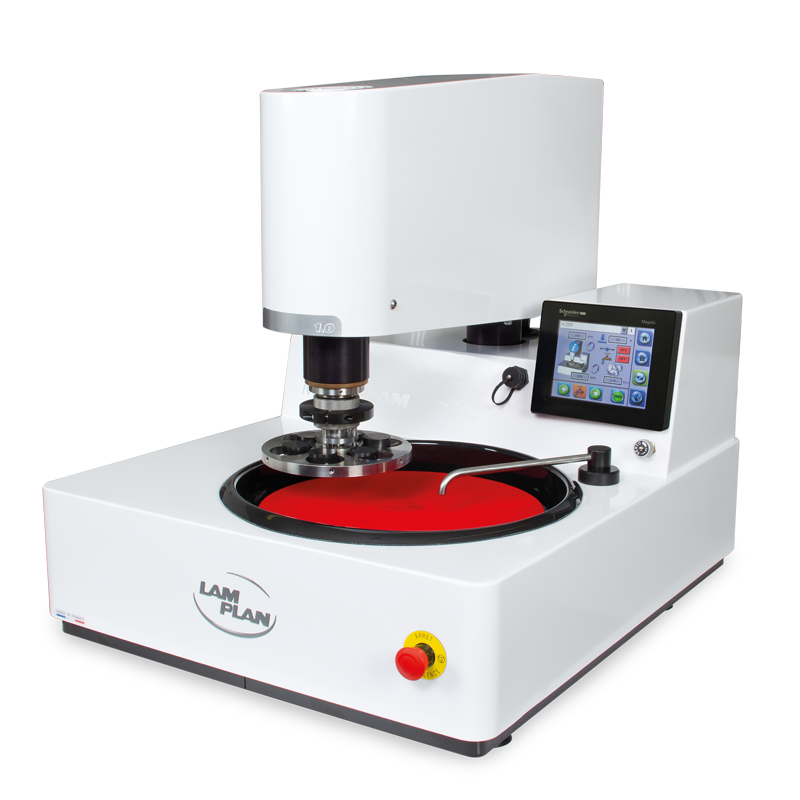

MASTERLAM®1.1

Automatic single-plate Ø 350 to 400 mm polishing machine, bidirectional rotation and variable speed.

-

Ø plates capacity400 mm

-

Plate rotation speed20 to 650 rpm

-

CapacitySample size 6 X Ø 60 mm

-

Programming60 storable programs

The MASTERLAM®1.1 is a central pressure machine. It is equipped with a 2,2 Kw main motor, a 250 W head motor and applicable pressure may reach 450 N.

Using the oscillating head allows you to make use the entire surface of the 350 or 400 mm diameter plate: the quality of flatness is improved, stock removal is increased and the service life of polishing supports is increased (uniform wear due to use of the entire surface of the plate.)

The specific capacities of the MASTERLAM®1.1 allow it to cope with most difficult applications, particularly in terms of large polishing surfaces where the torque and required pressure exceed the capabilities of standard equipment.

Design and advanced technology

Technical characteristics and equipment

-

Oscillation function

-

Stock removal control system

Downloads

Technical data MASTERLAM®1.1

Plates capacity | Ø 400 mm |

Body | Steel coated with epoxy paint |

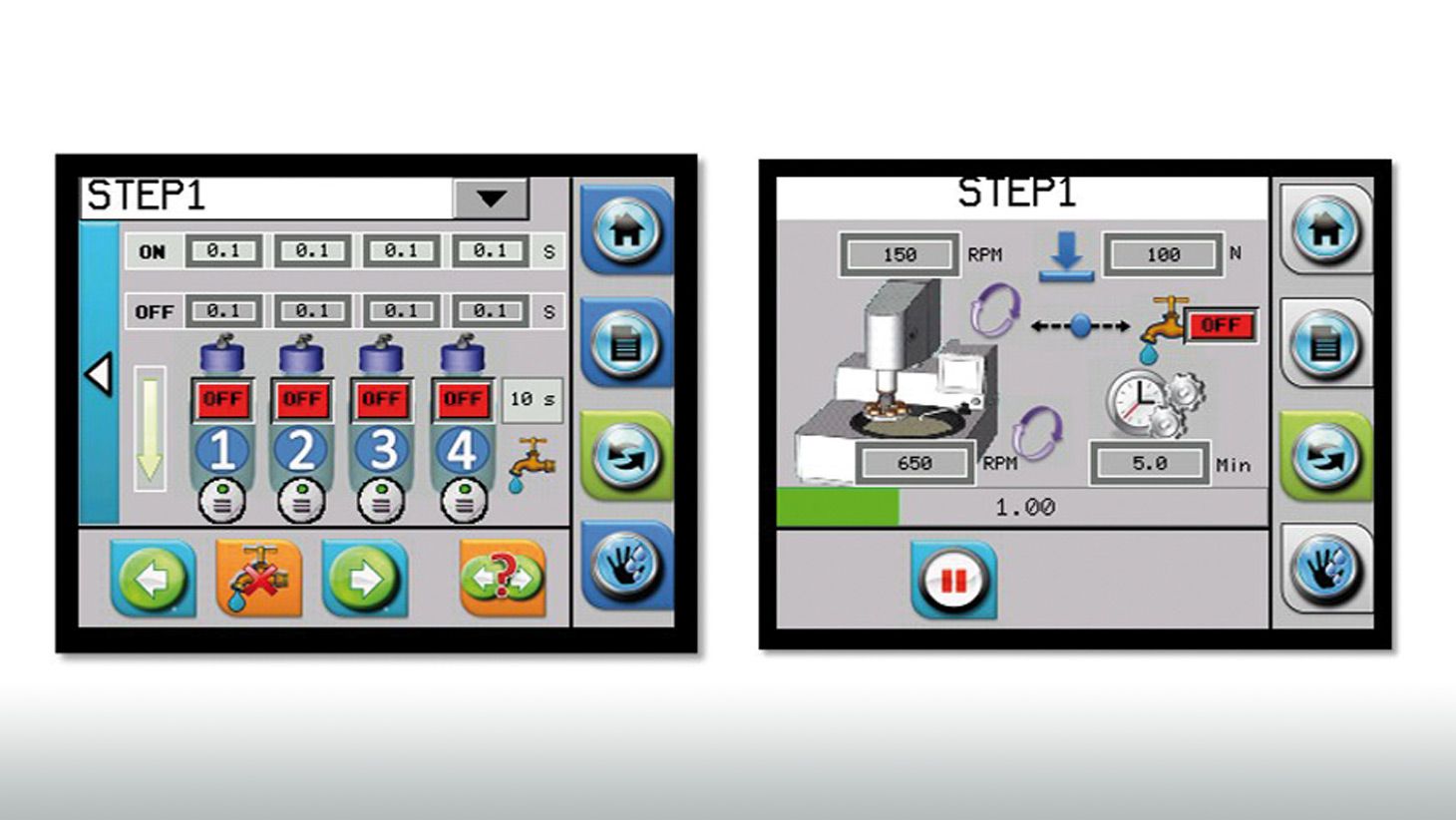

Controls | Touch screen (5,7“) |

Plate rotation speed | Variable from 20 to 650 rpm Bidirectional rotation |

Head’s speed | Variable from 10 to 150 rpm Bidirectional rotation |

Applicable load | 5 to 450 N central pressure |

Capacity | Sample size 6 X Ø 60 mm |

Oscillating head | Adjustable speed and amplitude |

Workspace lightening | LED |

Water inlet | Removable pipe, with flow rate adjustment and safety solenoid valve |

Programming | 60 storable programs, USB connector to backup programs and Ethernet port for networking |

Plate motor power | 2.2 kW |

Head motor power | 250 W |

Voltage | 230 V – 50 Hz single phase (25A) |

Pneumatic feed | 6 bars |

Dim. W x H x D | 800 x 670 x 712 mm |

Weight | 110 kg |

Reference | 60 ML110 00 |

Available accessories

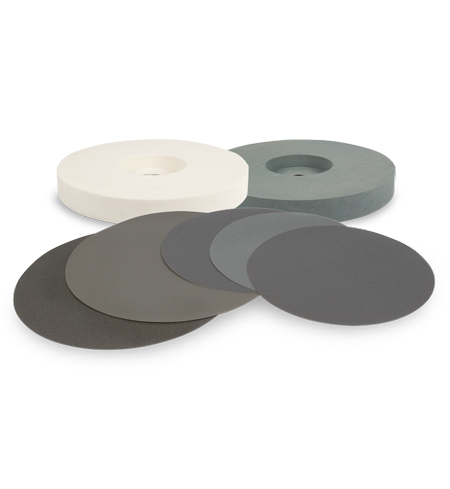

CAMEO® DISK Platinium grinding tool

For automatic polishing machines.

DISTRILAM® dosing unit

The DISTRILAM® automatic dispenser is controlled directly from the machine screen via a connector. It is instantly recognised by all MASTERLAM® polishing machines. The dispenser is equipped with 4 independent circuits consisting of 3 standard peristaltic pumps for precise dosing of diamond liquids and 1 higher flow peristaltic pump for dosing lubricant or colloidal abrasive. It operates without compressed air or electrical connection. The DISTRILAM® automatic dispenser is an essential accessory for automated use of MASTERLAM®. This device guarantees reproducible work and economical use of consumables.

Includes: dispenser, machine connection, 4-voice dispensing nozzle on magnetic base and 4 plastic bottles.

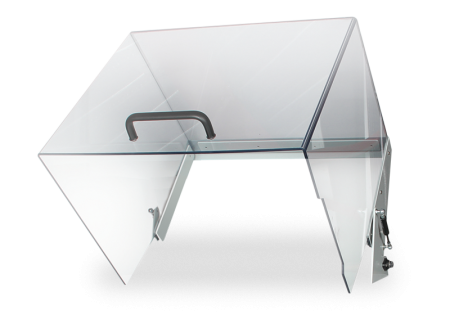

Transparent protective housing

The secured housing is a totally transparent protection compatible with the full range of MASTERLAM®. Its opening stops all movements of the machine*, it offers

an integral protection complying with the 2006/42/ CE and 2004/108/CE standards. The housing’s design preserves the accessibility of the plate and does not clutter the workspace. The touch screen is located outside of the secured zone; therefore, the commands are permanently accessible. For the MASTERLAM®1.0 and 3.0 the touch screen control panel is located on the right, a 195 mm space needs to be foreseen in addition to the machine width.

*However, the transparent secured housing authorises the plate rotation in the manual mode.

Required space for the MASTERLAM®1.1:

Width 880 mm – Height 910 mm

Aluminium plates

Aluminium plate Ø 400 mm

Sample holder central pressure

Ø 210 mm without cavity

Sample holder for irregular parts

Ø 160 mm central pressure sample holder for eccentric restriction of non-embedded complex geometric parts.

Levelling plate for central pressure sample holder

Ø 160 mm – 3 mm depth

Filtering / decantation 60 L tanks

- Filtering / sedimentation 60 L tank – 60 A0029 90

- Filtering / sedimentation 60 L tank with recirculation pump – 60 A0029 00