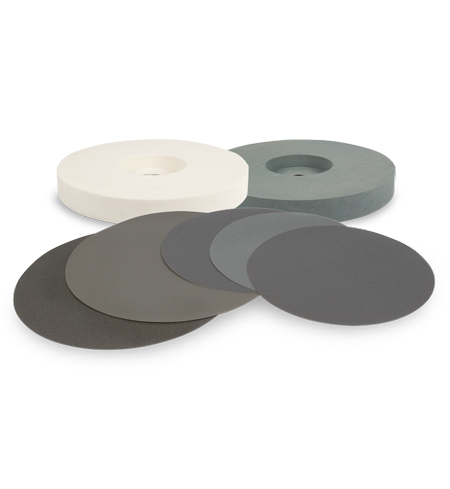

Grinding and prepolishing discs CAMEO®DISK

CAMEO®DISK Platinium, Silver, Gold, Rhodium, DMD range of grinding and prepolishing discs, dressing tools.

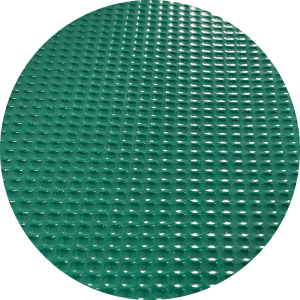

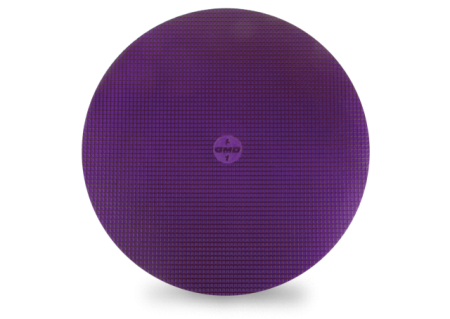

CAMEO®DISK: a patented honeycomb cell structure

Grinding and polishing are key steps in the preparation of a metallographic sample. It is the quality of these steps which will condition and optimise the rest of the process.

At the end of the grinding step, the sample’s aspect must be uniform and regular without altering the inherent flatness and the material.

The CAMEO®DISK’s performances in terms of stock removal reduce the work time on the part, thereby guaranteeing the sample’s inherent flatness, an indispensable condition to succeed with your metallographic analyse.

Stock removal

The honeycomb structure of CAMEO®DISK reduces the surface area in contact with the specimen to be polished. This reduces the pressure required to grind the specimen.

Reproducibility

The profile of the honeycomb cells was specially designed to optimise the circulation of the lubricant from one cavity to another. The abrasion residues are evacuated, guaranteeing a constant abrasive power and therefore a regularity of the result throughout the grinding and polishing steps.

Preparation quality

For a process usually performed with several SiC abrasive papers, LAM PLAN proposes you a single, reusable disc: the CAMEO®DISK. Contrary to SiC abrasive papers, CAMEO®DISK constant abrasion prevents the formation of deep disturbed layers during the first few seconds of grinding.

CAMEO®Disk Platinium

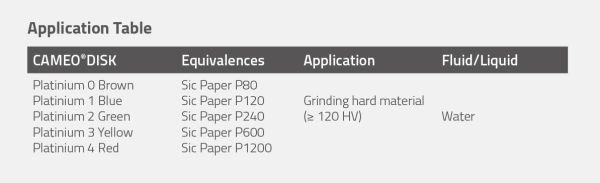

The CAMEO®DISK Platinium are diamond discs (fixed abrasive) which are ideal for a rapid grinding of metallographic samples.

The use of diamond integrated in the CAMEO®DISK Platinium honeycomb cell structure allows preserving a constant stock removal throughout the operation, which prevents the appearance of edge drops, including on samples of heterogeneous hardnesses.

CAMEO®DISK Platinium 0 Brun

Equivalence: Sic paper P80.

Application: Grinding hard material (≥ 120 HV).

Fluid/liquid: water.

| Box of 1 piece + 1 grinding stone | Self-adhesive | Magnetic |

| Ø in mm |

Ref. | Ref. |

| 200 | 09 CA170 20 | 09 CA570 20 |

| 250 | 09 CA170 40 | 09 CA570 40 |

| 300 | 09 CA170 50 | 09 CA570 50 |

CAMEO®DISK Platinium 1 Blue

Equivalence: Sic paper P120.

Application: Grinding hard material (≥ 120 HV).

Fluid/liquid: water.

| Box of 1 piece + 1 grinding stone | Self-adhesive | Magnetic |

| Ø in mm |

Ref. | Ref. |

| 200 | 09 CA140 20 | 09 CA540 20 |

| 250 | 09 CA140 40 | 09 CA540 40 |

| 300 | 09 CA140 50 | 09 CA540 50 |

CAMEO®DISK Platinium 2 Green

Equivalence: Sic paper P240.

Application: Grinding hard material (≥ 120 HV).

Fluid/liquid: water.

| Box of 1 piece + 1 grinding stone | Self-adhesive | Magnetic |

| Ø in mm |

Ref. | Ref. |

| 200 | 09 CA150 20 | 09 CA550 20 |

| 250 | 09 CA150 40 | 09 CA550 40 |

| 300 | 09 CA150 50 | 09 CA550 50 |

CAMEO®DISK Platinium 3 Yellow

Equivalence: Sic paper P600.

Application: Grinding hard material (≥ 120 HV).

Fluid/liquid: water.

| Box of 1 piece + 1 grinding stone | Self-adhesive | Magnetic |

| Ø in mm |

Ref. | Ref. |

| 200 | 09 CA160 20 | 09 CA560 20 |

| 250 | 09 CA160 40 | 09 CA560 40 |

| 300 | 09 CA160 50 | 09 CA560 50 |

CAMEO®DISK Platinium 4 Red

Equivalence: Sic paper P1200.

Application: Grinding hard material (≥ 120 HV).

Fluid/liquid: water.

| Box of 1 piece + 1 grinding stone | Self-adhesive | Magnetic |

| Ø in mm |

Ref. | Ref. |

| 200 | 09 CA180 20 | 09 CA580 20 |

| 250 | 09 CA180 40 | 09 CA580 40 |

| 300 | 09 CA180 50 | 09 CA580 50 |

CAMEO®Silver, Gold & Rhodium

The CAMEO®DISK Silver, Gold & Rhodium discs are non-diamond grinding discs developed to be used with Bio DIAMANT® abrasive products (free abrasives.)

Combined with the latest products of the Bio DIAMANT® range, the NEODIA® diamond abrasives will allow treating all types of materials.

The patented CAMEO®DISK honeycomb structure allows the uniform distribution of the periodically pulverised diamond abrasive suspension.

The use of the abrasive suspension is optimised, thereby reducing the diamond product’s consumption.

There are three variants of CAMEO®DISK designed with differing hardness suited for different types of material prepolished.

CAMEO®DISK Silver

Application: Medium to very hard ferrous alloys.

Abrasive liquid: 6 to 15 μm diamond abrasives NEODIA® M, P or F.

| Box of 2 pieces + 1 grinding tool | Self-adhesive | Magnetic |

| Ø in mm |

Ref. | Ref. |

| 200 | 09 CA120 20 | 09 CA520 20 |

| 250 | 09 CA120 40 | 09 CA520 40 |

| 300 | 09 CA120 50 | 09 CA520 50 |

CAMEO®DISK Gold

Application: soft non ferrous alloys.

Abrasive liquid: 3 to 6 μm diamond abrasives NEODIA® M, P or F.

| Box of 2 pieces + 1 grinding tool | Self-adhesive | Magnetic |

| Ø in mm |

Ref. | Ref. |

| 200 | 09 CA130 20 | 09 CA530 20 |

| 250 | 09 CA130 40 | 09 CA530 40 |

| 300 | 09 CA130 50 | 09 CA530 50 |

CAMEO®DISK Rhodium

Application: ceramics and cermets.

Abrasive liquid: 1 to 3 μm diamond abrasives NEODIA® M, P or F.

| Box of 2 pieces + 1 grinding tool | Self-adhesive | Magnetic |

| Ø in mm |

Ref. | Ref. |

| 200 | 09 CA100 20 | 09 CA500 20 |

| 250 | 09 CA100 40 | 09 CA500 40 |

| 300 | 09 CA100 50 | 09 CA500 50 |

CAMEO®DMD

The latest addition to the LAM PLAN range is a grinding disc designed for the preparation of ductile materials for metallography (aluminium and aluminium alloys, copper alloys, etc.).

LAM PLAN CAMEO®DISK DMD is the first diamond disc on the market that allows polishing ranges on ductile materials without abrasive paper.

LAM PLAN CAMEO®DISK DMD is the first diamond disc on the market that allows polishing ranges on ductile materials without abrasive paper.

The CAMEO®DISK DMD uses a new version* of our honeycomb structure combined with our expertise in abrasives. We have optimised the efficiency of the roughing stages for the most ductile metal alloys.

The performance of the new CAMEO®DISK DMD reduces disturbance at the grinding steps, enabling rapid transition to the polishing steps. It is a durable substrate that can be re-used many times with consistent efficiency.

PERFORMANCES

- Rapid sample levelling

- High material removal rate

- Low roughness

- Reduced deformation

- Simplified process.

CAMEO®DISK DMD 1

- Innovative structured disc with fixed abrasive

- Diamond-type abrasive with specific concentration

- New honeycomb structure. CAMEO®DISK DMD requires little pressure to be effective.

| Box 1 piece + 1 grinding stone | Self-adhesive | Magnetic |

| Ø (mm) |

Ref. | Ref. |

| 200 | 09 CA190 20 | 09 CA590 20 |

| 250 | 09 CA190 40 | 09 CA590 40 |

| 300 | 09 CA190 50 | 09 CA590 50 |

Grinding tools

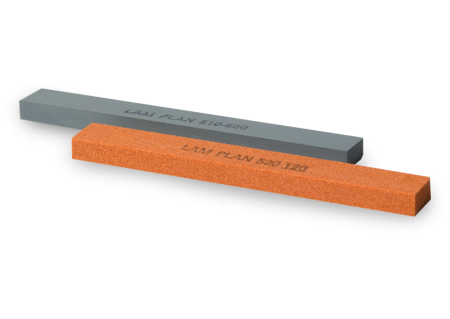

Abrasive stones for CAMEO®DISK

| 2 pieces | ||

| Type |

Dim. (mm) | Ref. |

| Grain 120 for Platinium 0, 1 & DMD | 6 x 13 x 100 | 98 59121 00 |

| Grain 400 for Platinium 2 | 6 x 13 x 100 | 98 59401 00 |

| Grain 600 for Platinium 3 & 4 | 6 x 13 x 100 | 98 59601 00 |

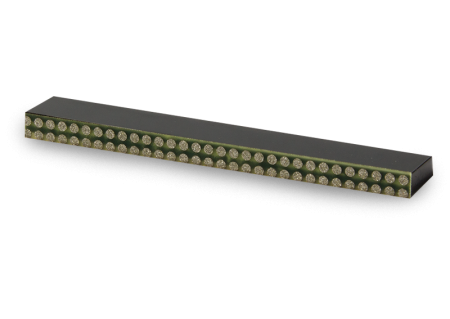

Diamond grinding tools for CAMEO®DISK

| 1 piece | ||

| Type |

Dim. (mm) | Ref. |

| For DMD (Automatic machines) | 5 x 15 x 100 | 06 MLCA1 60 |

| For Silver, Gold & Rhodium | 5 x 15 x 100 | 98 BD001 00 |

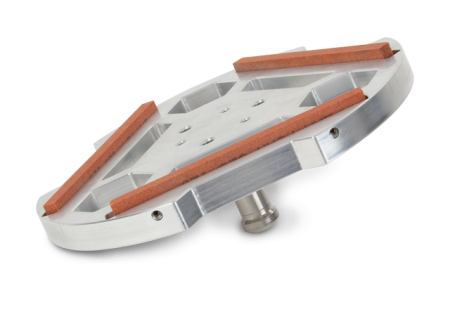

Grinding tool for automatic machines

| Type |

Characteristics | Qty. | Ref. |

| Grinding tool | For automatic machines | 1 | 06 MLCA1 60 |

Booster

Booster for CAMEO®DISK

Booster fluid is a new lubricant especially developed to be applied on the CAMEO®DISK Platinium during the polishing step.

Its specific formulation facilitates the use of the CAMEO®DISK Platinium 0, 1, 2, 3, 4 and DMD.

Ready-to-use, this new lubricant maintains the efficiency of the CAMEO®DISK constant in time and avoids the use of abrasive stone to regenerate the disc.

The main advantages are:

The main advantages are:

- Improves the efficiency of the CAMEO®DISK

- Keeps the efficiency constant in time

- Reduces water consumption

- Universal use, can be used on all kind of material

- Ready to use.

| Characteristics |

Packaging |

Ref. | |

| Ready to use lubricant fluid | 5 liters | 07 BP030 40 | |

To guarantee consistent results, the CAMEO®DISKs need to be adjusted periodically.

Various solutions are available; please contact your advisor.

Today, in most cases, the grinding of ductile materials is a time-consuming and expensive step, carried out using a series of SiC abrasive papers with different grains.

The disadvantages of this technique are as follows:

- The need for different grains to prepare the surface for polishing

- Very short and inconsistent abrasive paper life

- Extensive handling

- High long-term cost

- Large quantities of waste.