Catégorie : Box of knowledge

Guide d’enrobage

Lors de la préparation d’échantillons métallographiques, les échantillons tronçonnés sont généralement enrobés dans une résine pour obtenir des formes cylindriques en vue du polissage. Bien que l’enrobage puisse sembler être une étape auxiliaire dans la préparation des échantillons, il a des implications profondes sur le processus de polissage, déterminant ainsi la qualité du processus global de préparation des échantillons. Cela implique également l’importance du bon choix du processus d’enrobage et du consommable qui dépend de la nature de la matière à inspecter...

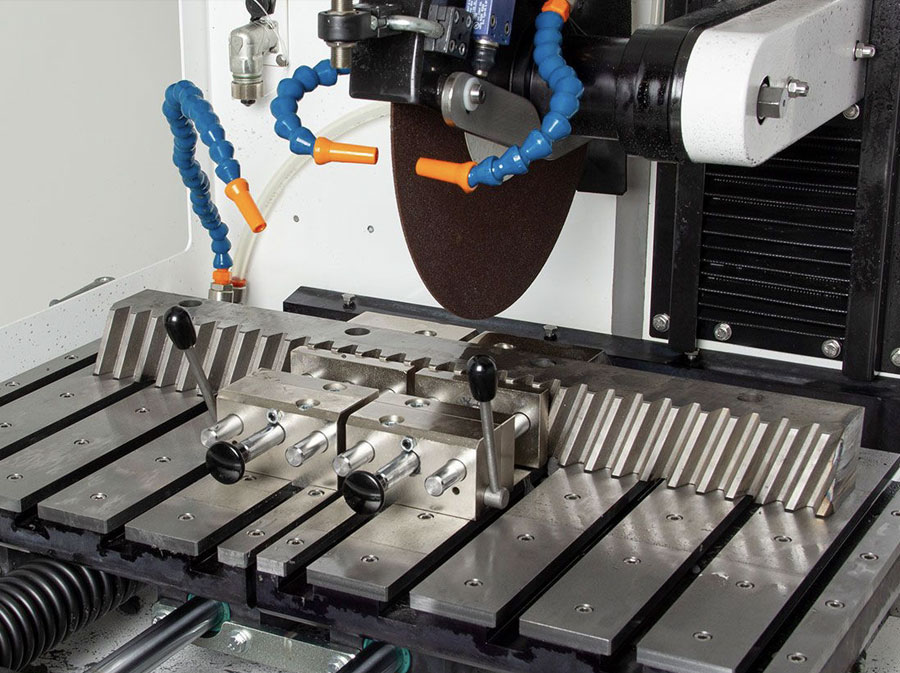

Choisir la bonne technologie de tronçonnage pour la préparation de vos échantillons métallographiques

Le tronçonnage consiste à découper un morceau d’échantillon en section transversale pour pouvoir l’analyser sous un microscope, suite à des étapes préalables de polissage.

Pour la métallographie, des machines de tronçonnage manuelles ou automatiques sont disponibles sur le marché pour effectuer ces opérations de coupe dans des conditions qui atténuent la déformation de la matière.

Choisir la bonne technologie de tronçonnage pour la préparation de vos échantillons métallographiques

Sommaire

Tronçonnage pour métallographie

Techniques de tronçonnage

Conclusions

Télécharger...

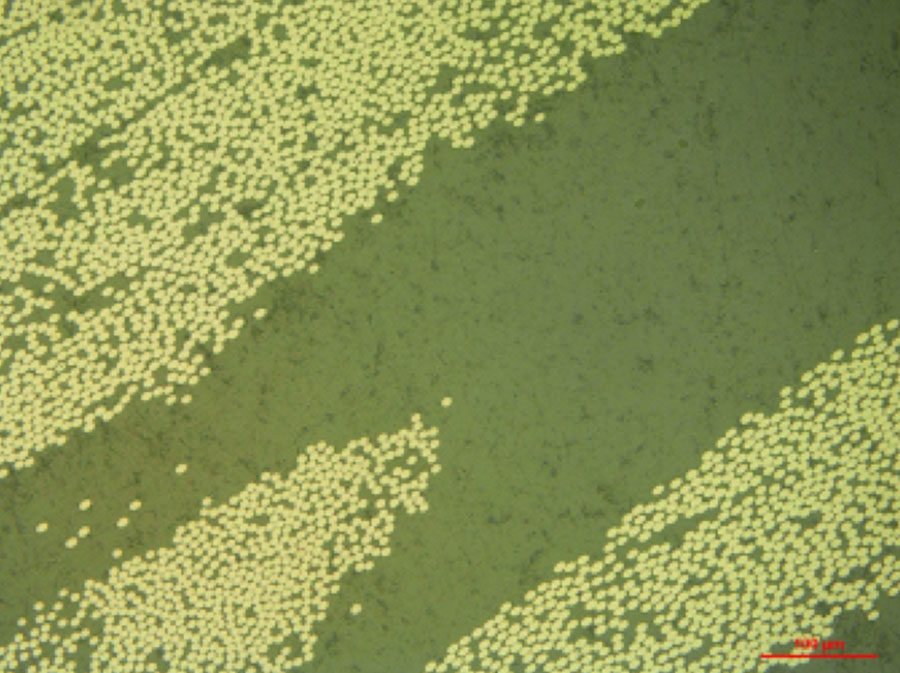

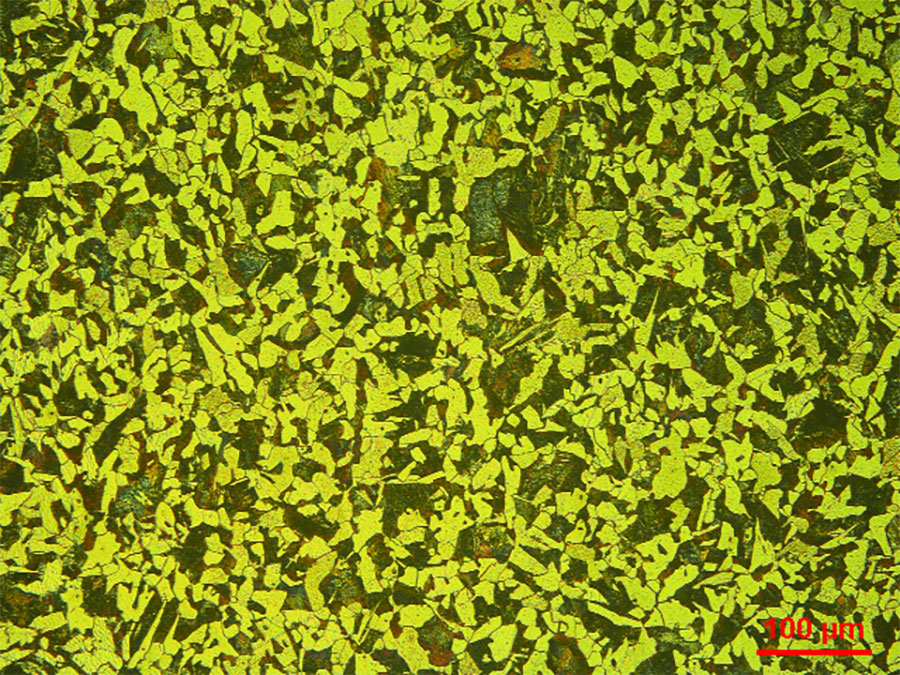

Métallographie des alliages de cuivre

Le cuivre est utilisé depuis des dizaines de milliers d’années et revêt donc une importance historique dans le domaine de la métallurgie. En tant que métal dont les alliages ont été explorés et mis au point depuis des millénaires, les alliages de cuivre sont connus pour leur conductivité thermique et électrique, et leur ductilité.Par exemple, le bronze est un alliage de cuivre qui a été le métal le plus exploré au cours de l’âge du bronze, bien nommé. En outre, leur résistance à la corrosion, leur solidité et leur abondance les rendent précieux pour de nombreuses industries.

...

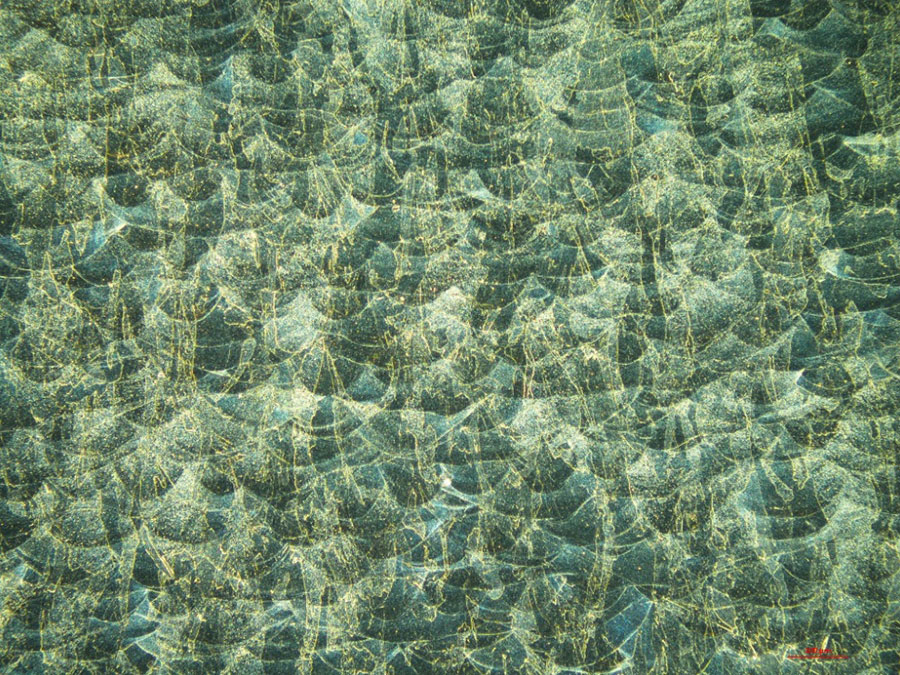

Matérialographie de Composites renforcés par des fibres

Les composites réunissent les avantages de deux domaines de matériaux différents. Une matière forme la matrice et une autre matière forme la phase de renforcement, leur combinaison donnant naissance à un composite. En fonction du matériau de la matrice, les composites peuvent être classés en composites à matrice polymère (PMC), composites à matrice métallique (MMC) et composites à matrice céramique (CMC). Les phases de renforcement sont généralement plus dures et plus résistantes que la matrice. De plus, les phases de renforcement peuvent être continues – comme les laminés ou les...

Métallographie des aluminiums

De par leur légèreté, les alliages d’aluminium offrent des solutions techniques pour les applications structurelles, ce qui les rend largement utilisés dans l’industrie aérospatiale et automobile. Leur résistance spécifique élevée les positionne avantageusement dans les tableaux de sélection des matériaux en ingénierie. Une autre qualité précieuse qu’ils possèdent est leur recyclabilité. Pour plusieurs composants aéronautiques, cela en fait des concurrents de poids face aux composites à matrice polymère. Toutefois, leur principal inconvénient est qu’ils perdent...

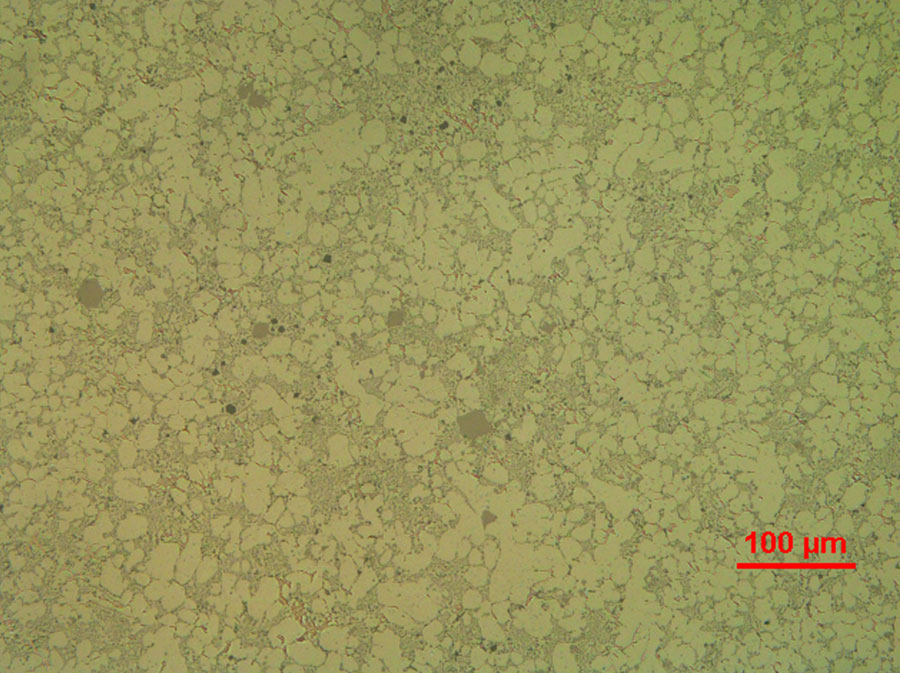

Métallographie pour la fabrication Additive

Au cours des dernières années, la fabrication additive (Additive Manufacturing) a révolutionné le domaine de la fabrication. Attirés par les divers avantages, notamment les innombrables possibilités de conception offertes par la fabrication additive, de plus en plus d’industries l’adoptent. Les industries aérospatiales et biomédicales ont été les premières à adopter ces technologies, qui évoluent rapidement. Aujourd’hui, on peut déjà voler dans des avions dotés de plusieurs composants fabriqués de manière additive, ou imprimer soi-même un implant spécialement conçu pour...

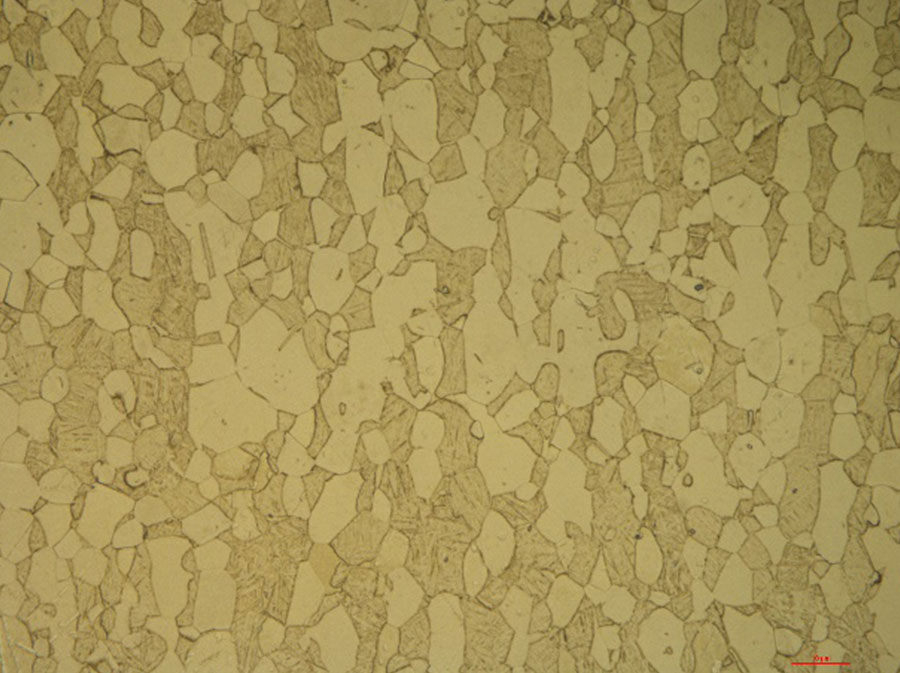

Métallographie des aciers

Les aciers sont largement utilisés dans une variété d’applications d’ingénierie allant des industries civiles aux industries aérospatiales et automobiles. La simplicité de la fabrication, le coût et les propriétés bien étudiées des alliages d’acier les rendent omniprésents en ingénierie. La plupart des aciers alliés sont fabriqués avec une chimie complexe en fonction des propriétés souhaitées. Cette page vous fournira les connaissances nécessaires pour effectuer efficacement la métallographie sans tracas.

Métallographie des aciers

Sommaire

1/ Métallographie pour les...

Métallographie du titane

Les alliages de titane sont connus pour leur résistance à la traction, leurs ténacités spécifiques élevées et leur résistance à la corrosion parmi les alliages non ferreux. Contrairement aux alliages d’aluminium, les alliages de titane résistent à des températures supérieures à 300° C, ce qui leur donne un avantage technique même s’ils sont plus chers. Grâce à leurs propriétés, ils sont fréquemment utilisés pour les composants dans les industries aéronautiques et aerospaciales. De plus, plusieurs alliages de titane sont biocompatibles, ce qui leur permet d’être largement...